OpenAM and new materials for FDM, along with software upgrades are part of new solutions customers have available

Stratasys Ltd. (NASDAQ: SSYS) is announcing updates to several Industrial and Healthcare Business Unit products and Stratasys Direct. These include a new open platform for the F900™ 3D printer, more on-demand 3D printing capabilities and a new high-performance material for its Fused Deposition Modeling line.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20240606767633/en/

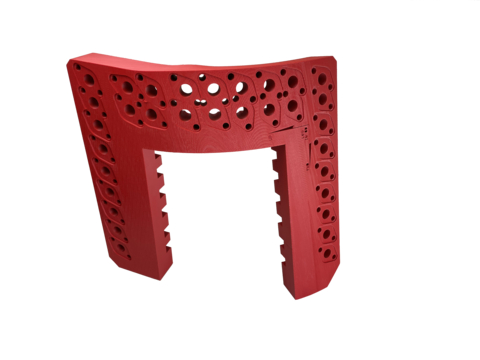

Stratasys makes several updates to products and materials, supporting customer growth. (Photo: Business Wire)

These new products and updates address customer feedback and are designed to unlock more opportunities and functionality for additive manufacturing capabilities. It is anticipated these enhancements will accelerate the speed of bringing products to market.

OpenAM comes to the F900

Stratasys OpenAM™ is a software application that enables the user to modify machine controls to achieve results beyond standard print settings. Already available for the Fortus 450®mc printer, Stratasys is now making its OpenAM software available for the F900 printer. This will allow for expanded functionality and capabilities and will unlock new materials for F900 users.

New VICTREX AM 200 material for FDM

A new material offering that opens the application potential for demanding industries like aerospace and medical, where material properties are critical components of a 3D-printed solutions. This new high-performance, high-strength, validated material, VICTREX AM™ 200, will be available for the Fortus 450mc and the F900. VICTREX AM 200 is a PEEK-based polymer that is temperature, corrosion, and chemical resistant, with excellent mechanical properties which can be utilized with soluble and breakaway support material.

Carbon Fiber Visual Print Option for the F-Series

Carbon Fiber Visual Print Option is a new 5-slice (0.005”) layer height across the F-123 Series™ line of printers that is coming later this month for FDM®ABS-CF10. It produces a smoother surface finish, to provide the perfect finish when a part’s visual appearance is important to the application. It is built for applications that demand the durability of a carbon-filled polymer, but also requires a visually appealing result without additional post-processing.

F770 Adds New Colors

The F770® printer can now print in multiple colors, in addition to its original single ivory color. Six new ASA colors, including red, white, light gray, black, blue, and yellow, will allow for more application versatility with FDM® ASA and ABS-M30 tried-and-true engineering plastics. The new colors enable printing without painting or other post-production marking, allowing parts to be available much faster, increasing productivity.

Somos NeXt Validated for SLA

Somos® NeXt™ is now a validated material for Stratasys NEO® stereolithography 3D printers. Somos NeXt is a resin with superior strength and can be used in automotive and consumer products, along with other applications, including prototyping, to produce durable, accurate and detailed parts.

New GrabCAD Software Print Integration Enhances On-Demand 3D Printing Capabilities

Stratasys has introduced Parts on Demand by GrabCAD, a new integration that synchronizes the company's software platform with Stratasys Direct. This addition allows GrabCAD Print™ customers to access Stratasys Direct’s fleet of 3D printers, allowing for larger and more intricate designs, a selection of more than 50 engineered materials, and the assurance of stringent quality inspections.

“In making these upgrades and enhancements, we are taking and applying feedback from our customers to help them better meet their additive manufacturing needs,” said Rich Garrity, Chief Industrial Business Officer, Stratasys. “Additive manufacturing is on the cusp of a new era, where it works side-by-side with traditional means of manufacturing. Bringing new products and updates, increases our ability to become part of the manufacturing ecosystem.”

About Stratasys

Stratasys is leading the global shift to additive manufacturing with innovative 3D printing solutions for industries such as aerospace, automotive, consumer products and healthcare. Through smart and connected 3D printers, polymer materials, a software ecosystem, and parts on demand, Stratasys solutions deliver competitive advantages at every stage in the product value chain. The world’s leading organizations turn to Stratasys to transform product design, bring agility to manufacturing and supply chains, and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the Stratasys blog, Twitter, LinkedIn, or Facebook. Stratasys reserves the right to utilize any of the foregoing social media platforms, including Stratasys’ websites, to share material, non-public information pursuant to the SEC’s Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

Stratasys, Stratasys Direct, F900, OpenAM, Fortus, 450mc, VICTREX, VICTREX AM, F123 Series, FDM, F770, ABS-M30, SOMOS, NeXt, NEO, GrabCAD and GrabCAD Print are trademarks or registered trademarks of Stratasys Ltd. and/or its affiliates. All other trademarks are the property of their respective owners.

To learn more about Select Additive Technologies, visit www.selectadditive.com, LinkedIn, or Instagram.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240606767633/en/

Contacts

Media and Investor contacts:

Stratasys Corporate & North America

Chris Reese

chris.reese@stratasys.com

+1 651 357 0877

Brazil, Central America and South America

Erica Massini

Erica.Massini@stratasys.com

+55 (11) 2626-9229

Stratasys Corporate & Israel

Erik Snider

Erik.Snider@stratasys.com

+972 74 745 6053

Asia

Kalyani Dwivedi

Kalyani.Dwivedi@stratasys.com

+91 80 6746 2606

Investor Relations

Yonah Lloyd

Yonah.Lloyd@stratasys.com

+972 74 745 4919