TrendMiner offers a contextualized industrial data fabric by allowing custom calculations to write into events for deeper operational insights.

Personalization of reports and dashboards help to convey the right message shared into the organization.

SAP Digital Manufacturing and TrendMiner bring a true 360° view on operations.

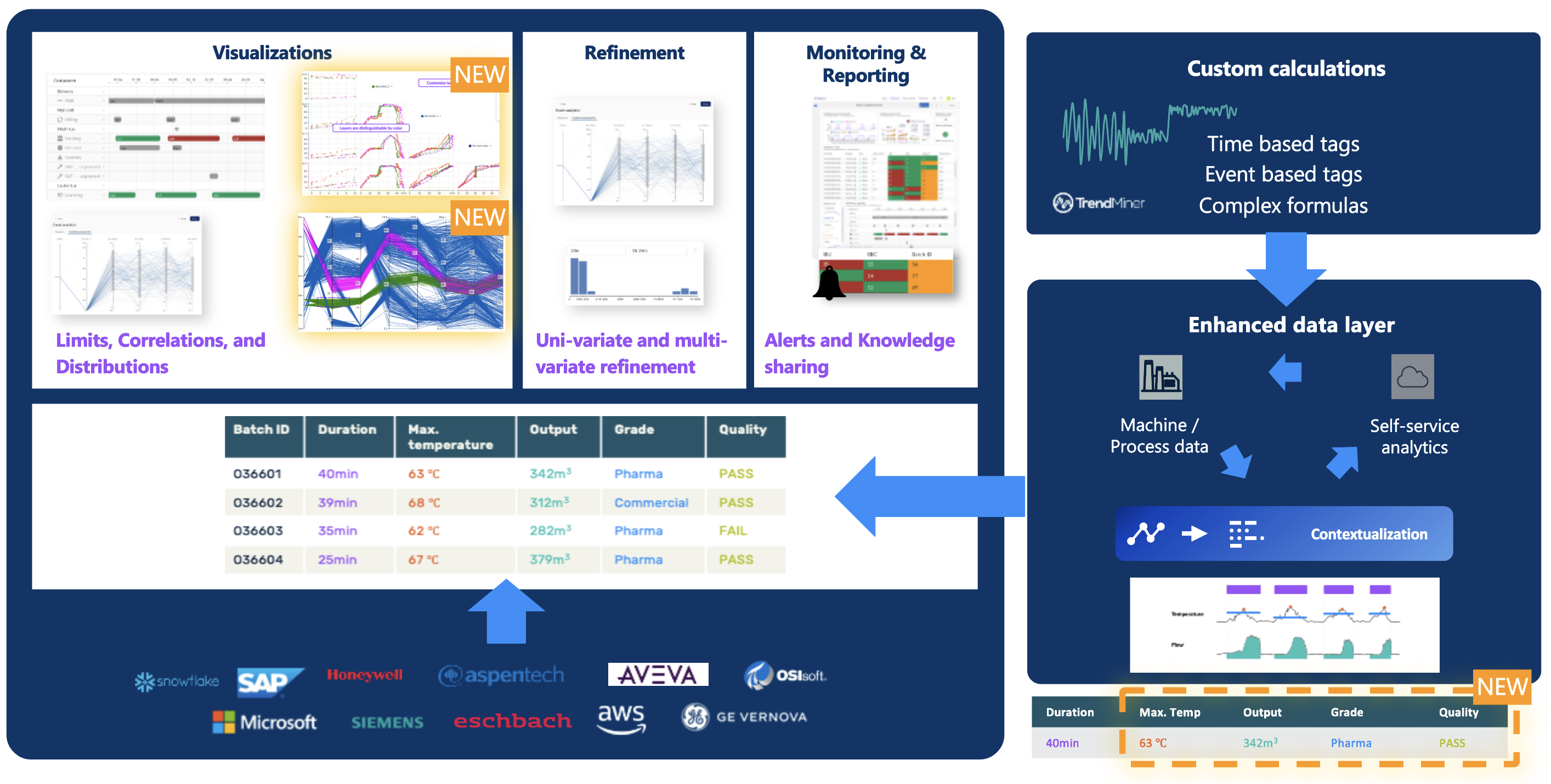

HASSELT, BELGIUM / ACCESSWIRE / August 8, 2024 / TrendMiner, the Industrial AI & Analytics platform, takes a next step toward offering a contextualized data fabric for industrial data with the launch of its 2024.R2 release. This industrial data fabric is further enforced with the integration of SAP Digital Manufacturing. Also called "Enhanced Data Layer," TrendMiner's industrial data fabric forms the basis for all self-service capabilities of the platform. Personalization of reports and dashboards help improve awareness and understanding throughout the organization. This accelerates data-driven decision-making at every level of analytics maturity.

Industrial Data Fabric for advanced event analysis

Custom calculations that use complex formulas, time series data, operational events and human knowledge are stored as properties to events to improve operational insights. On top of these calculations, newly added visualization options for events and new chart formatting options for data refinement ensure that the right insights are used. This leads to faster data-driven decision making by all operational experts.

"By enabling calculations to be applied to operational events, the TrendMiner ‘Enhanced Data Layer' is enriched with new operational insights, including human-generated shop floor expertise for additional context."

-- Julian Pereira, Director of Products

Personalized Reports & Dashboards for Effective Communication

Every user of the TrendMiner platform can personalize his or her view with the new chart alias option for tags and attributes. When combined with the options for grouping, coloring, and scaling, users can give more meaning to the view. This helps convey the right message in reports and dashboards for users, the team, or the entire organization.

TrendMiner's 2024.R2 release offers a complete platform to facilitate event analytics and operationalize industrial data.

SAP & TrendMiner: A 360° View on Operations

SAP Digital Manufacturing and TrendMiner bring a true 360° view to operations by blending equipment and MES data. This makes it easy to combine processed time-series data with event data and asset hierarchies from SAP. Operational experts can use this information for monitoring, predicting, and delivering product quality.

The new integration with SAP Digital Manufacturing allows everybody from the shopfloor to the boardroom to analyze any type of industrial data, anytime and everywhere, to increase cross-team collaboration and knowledge sharing.

Further Information

For details about all the new capabilities and improvements in the TrendMiner 2024.R2 release, visit www.trendminer.com. Users of the TrendMiner software will get more information via other communication channels.

About TrendMiner

TrendMiner, part of the Proemion holding, delivers Industrial AI & Analytics software to optimize process performance in chemical, petrochemical, oil & gas, pharmaceutical, optics, semi-conductors, food & beverage, metals & mining, water & wastewater, and other process manufacturing industries. TrendMiner unlocks the full potential of IIoT (Industrial Internet of Things) data infrastructure, regardless of vendor, and taps into the available human intelligence for making data-driven decisions. The solution includes standard integrations with a wide range of data sources, such as OSIsoft PI, Yokogawa Exaquantum, AspenTech IP.21, Honeywell PHD, GE Proficy Historian, Wonderware InSQL, Cumulocity, Aveva Data Hub, AWS S3, AWS IoT SiteWise, Amazon Timestream, Microsoft Azure Data Lake, Azure Data Explorer, Microsoft Fabric, and SAP's S/4 HANA, and DMC.

TrendMiner empowers everyone in manufacturing operations across multiple locations with powerful yet intuitive capabilities to iteratively generate and validate real-time context-aware time-series insights individually and as a team. Search, diagnostic, and predictive capabilities help speed up root cause analysis, define optimal processes, and configure early warnings to monitor production 24/7. TrendMiner helps operators make data-driven decisions to improve production quality, meet business objectives, and increase profitability.

Media Contact

Matt Saxton

TrendMiner Editor

+1 408-490-5345

matthew_saxton@softwareag.com

SOURCE: TrendMiner N.V.

View the original press release on accesswire.com