Highlights:

- Metallurgical work completed on representative oxide, transition and fresh rock composite samples ranging in grade from 2.36% Cg for fresh rock to 3.04% Cg for oxide samples.

- Bond abrasion and work index testing show low to medium abrasion and low energy requirements.

- Open circuit flotation tests resulted in excellent concentrates grade ranging from 94.4% Cg for fresh rock materials to 99.5% Cg for oxide samples with a simple flowsheet that maximizes graphite recovery and minimizes flake degradation.

- The open circuit graphite recoveries were high, ranging between 87.5% and 91.5%.

- Given the superior response of the oxide and transitional material, the next phase of work will investigate mining pit design to maximize processing of oxide and transitional material early in the project life and postpone mining of the fresh ore in order to decrease initial CAPEX, lower OPEX and target improved project economics.

- The NI43-101 Preliminary Economic Assessment results for BamaStar are scheduled for release in August 2024.

VANCOUVER, BC / ACCESSWIRE / June 25, 2024 / South Star Battery Metals Corp. ("South Star" or the "Company") (TSXV:STS)(OTCQB:STSBF) is pleased to announce successful results from the ongoing metallurgical process development program for the Bama Star graphite project in Alabama, USA.

The test program is designed to support the upcoming National Instrument ("NI") 43-101 Preliminary Economic Assessment ("PEA") study, which is planned for completion in August 2024. For this purpose, sub-samples of oxide, transitional, and fresh bulk samples were shipped to SGS Lakefield in Canada for scoping-level metallurgical testing. The oxide sample represents the near-surface material and the fresh sample the ore from deeper within the deposit that has not been exposed to any weathering. The transition sample represents the intermediate zone between oxide and fresh horizons. The SGS scope of work included comminution and flotation testing.

The three composites were subjected to Bond abrasion, Bond rod mill grindability, Bond ball mill grindability, and SMC testing. The results of the comminution tests are summarized in Table 1. The oxide sample yielded the lowest abrasivity and grinding energy requirements and both abrasivity and grinding energy requirements increased gradually with greater depth. Overall, grinding energy requirements are considered low to medium when compared to other graphite projects, which will help to minimize energy requirements of the operation.

Table 1: Comminution Test Results

The three composites were submitted for a chemical analysis and pertinent results are presented in. Table 2 presents the head grades by composite sample types, which ranged between 2.36% C(g) for the transitional sample and 3.04% C(g) for the oxide sample.

Table 2: Head Grades of Ore Types (total carbon / graphitic carbon / sulfides)

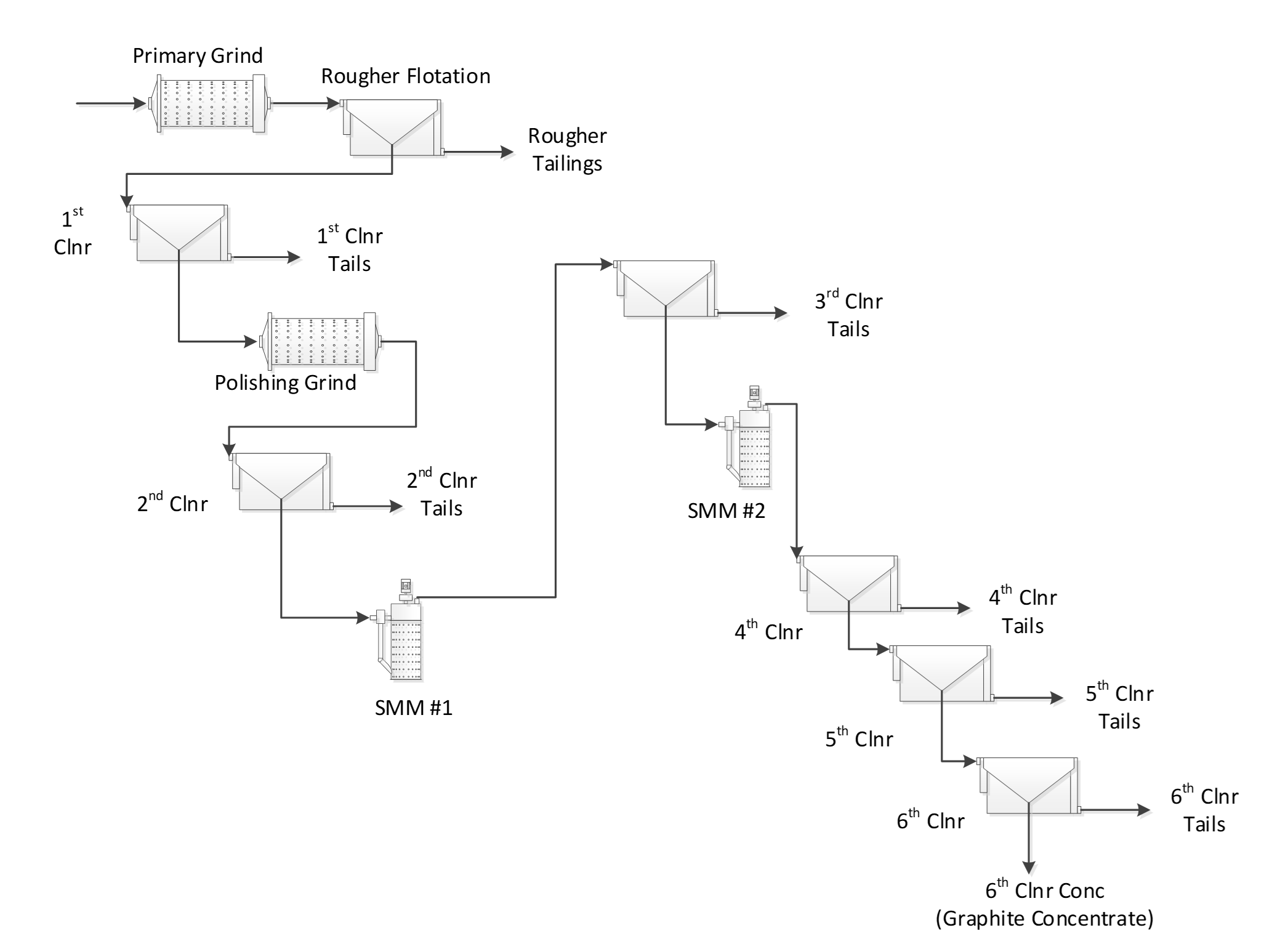

Flotation testing was conducted to determine the flowsheet and conditions to produce a concentrate grading at least 94% C(t) that maximizes graphite recovery and minimizes flake degradation. The simple flowsheet presented in Figure 1 was employed to generate the flotation concentrate. Flotation conditions and reagent dosages were adjusted based on observations made during testing.

The results of open circuit cleaner tests on the three composites are shown in Table 3. The highest concentrate grade of 99.5% C(g) was achieved for the oxide sample and grades gradually decreased with deposit depth to 94.4% C(g) for the fresh sample. All three ore types achieved the targeted minimum grade of 94% C(g).

The open circuit graphite recoveries were high ranging between 87.5% and 91.5%. During closed circuit operation, additional graphite is expected to be recovered into the final concentrate since graphite in intermediate streams is not rejected as tailings.

Table 3: Open Circuit Cleaner Flotation Tests

Figure 1: Conceptual BamaStar Flowsheet

The graphite concentrate of the three ore types was subjected to a size fraction analysis to determine the mass distribution into different size fractions and the corresponding total carbon grades. The results are presented in Table 4. Between 17.9% and 24.4% of the concentrate mass reported to the plus 150 microns size fraction and the balance to the minus 150 microns product. The total carbon grades were consistent for most size fractions and decreased for the minus 45 microns fines. This grade profile is commonly observed for graphite projects since the smallest size fraction is the most difficult to liberate during regrinding and frequently contains entrained gangue minerals.

Table 4: Results of Size Fraction Analysis of Graphite Concentrates

It should be noted that the flowsheet and conditions were not optimized, but instead the tests were developed utilizing a flowsheet and conditions that has proven successful for similar projects. In the next phase of testing, a systematic process development program will be carried out to optimize the flowsheet and reagent regime. The objective of the process development program will be to maximize concentrate grade and recovery while minimizing capital and operating costs for the circuit.

Given the superior response of the oxide and transitional material, the next phase of work will optimize mining pit design to maximize processing of oxide and transitional material early in the project life and postpone mining of the fresh ore. This approach will allow a phased approach of capital expenditure since grinding energy requirements for primary and regrind applications are much lower for the near-surface ore types.

Richard Pearce, CEO of South Star, remarked, "These are great results confirming the excellent nature of the graphite resource at BamaStar and the ease with which it can be transformed into high grade concentrates. Low abrasion and energy requirements will help lower our CAPEX/OPEX. These are initial results suitable for the upcoming PEA, and the flowsheet is not optimized yet. The upcoming feasibility study work will aim to optimize the flowsheet and improve on these results. The ability to achieve 88% recoveries with 99.5% Cg in the oxide portion of the resource with just mechanical methods are exceptional results. Once optimized, we hope to improve on these metrics. Potentially, this could open a wide range of value-add markets for the Company without having to purify and significantly improve our development in the short-term. Our team continues to focus on executing our strategic plan to create near-term production with high-quality, low cost, scalable assets in Tier 1 jurisdictions. Santa Cruz is scheduled to start commercial production in Q3 of 2024, and BamaStar is an important next step for our development."

# # #

About South Star Battery Metals Corp.

South Star Battery Metals Corp. is a Canadian battery metals project developer focused on the selective acquisition and development of near-term production projects in the Americas. South Star's Santa Cruz Graphite Mine, located in Southern Bahia, Brazil is the first of a series of industrial and battery metals projects that will be put into production. Brazil is the second-largest graphite-producing region in the world with more than 80 years of continuous mining. Santa Cruz has at-surface mineralization in friable materials, and successful large-scale pilot-plant testing (> 30t) has been completed. The results of the testing show that approximately 65% of graphite concentrate is +80 mesh with good recoveries and 95%-99% graphitic carbon (Cg). With excellent infrastructure and logistics, South Star is fully funded for Phase 1, and the construction and commissioning are nearing completion. Santa Cruz will be the first new graphite production in the Americas since 1996, with Phase 1 commercial production of 12,000 tpy of concentrates projected in Q3 2024. Phase 2 production (25,000 tpa) is partially funded and planned for Q1 2027, while Phase 3 (50,000 tpa) is scheduled for 2028. All environmental permits and mining licenses for Phases 1, 2 and 3 have been approved by Brazilian regulatory agencies.

South Star's second project in the development pipeline is strategically located in Alabama in the center of a developing electric vehicle, aerospace, and defense hub in the southeastern United States. The BamaStar Project includes a historic mine active during the First and Second World Wars. A NI43-101 technical report with the maiden resource estimate has been filed on SEDAR in April 2023. Trenching, two drilling campaigns, sampling, analysis, and preliminary metallurgical testing have been completed. A NI43-101 Preliminary Economic Assessment("PEA"), incorporating a downstream value-add/battery anode plant is planned to be completed on BamaStar in August 2024. The testing indicates a traditional crush/grind/flotation concentration circuit that achieved grades of approximately 94-99% Cg with approximately 90% recoveries. The Company has received a US$3.2 million grant from the U.S, Department of Defense under the Defense Production Act Title III authorities utilizing funds appropriated by the Inflation Reduction Act, to advance a NI43-101 Feasibility Study ("FS") for the BamaStar Graphite Project, on delivery of the PEA. South Star is executing on its plan to create a multi-asset, diversified battery metals company with near-term operations in strategic jurisdictions. South Star trades on the TSX Venture Exchange under the symbol STS, and on the OTCQB under the symbol STSBF.

South Star is committed to a corporate culture, project execution plan and safe operations that embrace the highest standards of ESG principles, based on transparency, stakeholder engagement, ongoing education, and stewardship. To learn more, please visit the Company website at http://www.southstarbatterymetals.com.

Qualified Person

Mr. Oliver Peters, a Principal Metallurgist and President of Metpro Management Inc., is a Qualified Person within the meaning of NI 43-101. Mr. Peters is satisfied that the analytical and testing procedures used are standard industry operating procedures and methodologies, and he has reviewed, approved and verified the technical information disclosed in this news release, including sampling, analytical and test data underlying the technical information.

On behalf of the Board,

MR. RICHARD PEARCE

Chief Executive Officer

For additional information, please contact:

South Star Investor Relations

Email: invest@southstarbatterymetals.com

Phone: +1 (604) 706-0212

Website: www.southstarbatterymetals.com

Twitter:https://twitter.com/southstarbm

Facebook: https://www.facebook.com/southstarbatterymetals

LinkedIn: https://www.linkedin.com/company/southstarbatterymetals/

YouTube: South Star Battery Metals - YouTube

CAUTIONARY STATEMENT

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this press release.

Forward-Looking Information

This press release contains "forward-looking statements" within the meaning of applicable securities legislation. Forward-looking statements relate to information that is based on assumptions of management, forecasts of future results, and estimates of amounts not yet determinable. Any statements that express predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance are not statements of historical fact and may be "forward-looking statements". Forward-looking statements in this press release include, but are not limited to statements regarding moving Santa Cruz into production and scaling operations as well as advancing the Alabama project; and the Company's plans and expectations.

Forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ from those reflected in the forward-looking statements, including, without limitation: risks related to failure to obtain adequate financing on a timely basis and on acceptable terms; risks related to the outcome of legal proceedings; political and regulatory risks associated with mining and exploration; risks related to the maintenance of stock exchange listings; risks related to environmental regulation and liability; the potential for delays in exploration or development activities or the completion of feasibility studies; the uncertainty of profitability; risks and uncertainties relating to the interpretation of drill results, the geology, grade and continuity of mineral deposits; risks related to the inherent uncertainty of production and cost estimates and the potential for unexpected costs and expenses; results of prefeasibility and feasibility studies, and the possibility that future exploration, development or mining results will not be consistent with the Company's expectations; risks related to commodity price fluctuations; and other risks and uncertainties related to the Company's prospects, properties and business detailed elsewhere in the Company's disclosure record. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in forward-looking statements. Investors are cautioned against attributing undue certainty to forward-looking statements. These forward-looking statements are made as of the date hereof and the Company does not assume any obligation to update or revise them to reflect new events or circumstances. Actual events or results could differ materially from the Company's expectations or projections.

SOURCE: South Star Battery Metals Corp.

View the original press release on accesswire.com