In a pivotal move signaling the future of industrial resilience, a recent workshop on Corrosion and Wear Resistant Coating Technology for Micro, Small, and Medium Enterprises (MSMEs) has underscored not just the critical importance of protecting industrial assets, but also the transformative role Artificial Intelligence (AI) is playing in this traditionally materials-science-driven field. Held against the backdrop of an accelerating digital transformation, the event highlighted how advanced coatings, increasingly augmented by AI, are becoming indispensable for extending equipment lifespan, reducing operational costs, and enhancing safety across diverse industrial applications, particularly for the often resource-constrained MSME sector.

The workshop served as a crucial platform to educate MSMEs on the latest breakthroughs, emphasizing that the era of passive protection is giving way to dynamic, intelligent coating solutions. These advancements are not merely incremental; they represent a paradigm shift driven by AI's ability to optimize material design, application processes, and predictive maintenance. This integration promises to democratize access to high-performance protective technologies, allowing smaller players to compete on durability and efficiency with larger industrial entities.

The Intelligent Skin: AI's Deep Dive into Coating Technology

The core of this technological revolution lies in the sophisticated application of AI across the entire lifecycle of corrosion and wear-resistant coatings. Traditionally, developing new coatings was a time-consuming process of trial and error, heavily reliant on empirical data and expert intuition. However, AI algorithms are now capable of analyzing vast datasets comprising material properties, environmental conditions, and performance metrics, thereby accelerating the discovery and design of next-generation coatings. This includes the development of nanomaterial-based coatings, such as those incorporating graphene for superior barrier properties, and complex hybrid coatings that offer multi-faceted protection against various environmental stressors.

A significant leap forward is the emergence of smart and self-healing coatings, a concept once confined to science fiction. AI plays a critical role in engineering these materials to autonomously repair damage, sense environmental changes, and respond dynamically—for instance, by altering properties or color to indicate overheating or stress. This differs dramatically from previous approaches, where coatings offered static protection, requiring manual inspection and reapplication. Furthermore, AI optimizes coating application processes in real-time, ensuring uniformity and consistency through precise parameter adjustments, leading to fewer defects and reduced material waste. AI-driven cameras and sensors provide real-time quality assurance, detecting imperfections with accuracy far exceeding human capabilities. Initial reactions from the material science and industrial communities are overwhelmingly positive, recognizing AI as a force multiplier for innovation, promising coatings that are not only more effective but also more sustainable and cost-efficient.

Reshaping the Industrial Landscape: AI's Competitive Edge

The integration of AI into corrosion and wear-resistant coating technology carries profound implications for companies across the industrial spectrum. MSMEs, the primary focus of the workshop, stand to gain immensely. By adopting AI-enhanced coating solutions, they can significantly extend the operational life of their machinery and infrastructure, transforming significant capital investments into long-term assets. This directly translates into reduced maintenance and replacement costs, minimizing downtime and boosting overall operational efficiency. Companies specializing in AI and machine learning, particularly those focused on materials science and industrial automation, are poised to benefit from the increased demand for intelligent coating solutions and the underlying AI platforms that power them.

For traditional coating manufacturers, the competitive landscape is shifting. Those that embrace AI for material design, process optimization, and quality control will gain a significant strategic advantage, offering superior, more reliable, and customizable products. Conversely, companies slow to adopt these technologies risk disruption, as their offerings may fall behind in performance and cost-effectiveness. AI-driven coatings enable a shift from generic, off-the-shelf solutions to highly tailored protective layers designed for specific industrial environments and equipment, fostering a new era of personalized industrial protection. This market positioning, centered on advanced, AI-powered durability, will become a key differentiator in a competitive global market.

Beyond Protection: AI's Broader Impact on Industrial Sustainability

The emergence of AI in coating technology fits seamlessly into the broader AI landscape, particularly the trend of applying AI to complex material science challenges and industrial process optimization. Its impact extends beyond mere equipment protection, touching upon critical areas like industrial sustainability, safety, and economic development. By prolonging the life of assets, AI-enhanced coatings contribute significantly to sustainability goals, reducing the need for new manufacturing, decreasing resource consumption, and minimizing waste. The ability of AI to predict corrosion behavior through real-time monitoring and predictive maintenance also enhances safety by preventing unexpected equipment failures and allowing for proactive intervention.

However, this advancement is not without its considerations. The initial investment in AI-driven systems and the need for specialized skills to manage and interpret AI outputs could pose challenges, particularly for smaller MSMEs. Comparisons to previous AI milestones, such as AI in complex manufacturing or supply chain optimization, highlight a consistent theme: AI's power lies in its ability to process vast amounts of data and identify patterns that human analysis might miss, leading to efficiencies and innovations previously unimaginable. This application to foundational industrial processes like protective coatings underscores AI's pervasive and transformative potential across all sectors.

The Future is Coated: Autonomous and Adaptive Protection

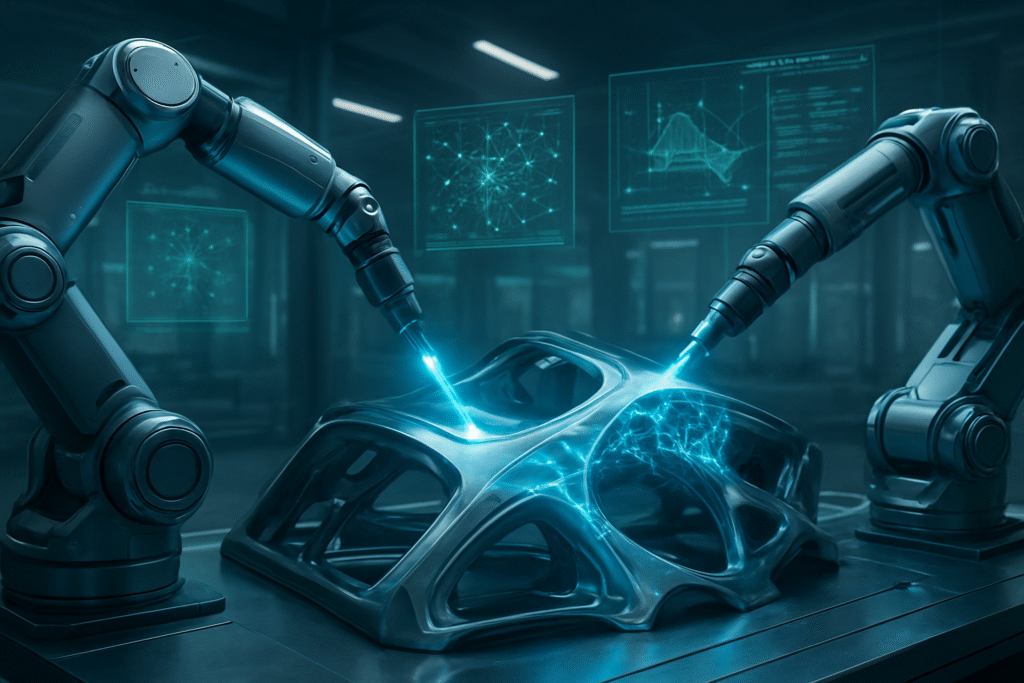

Looking ahead, the trajectory for AI in corrosion and wear-resistant coating technology is one of increasing autonomy and sophistication. Near-term developments are expected to focus on more refined AI models for predictive maintenance, leading to hyper-personalized coating solutions that adapt to minute environmental changes. We can anticipate the advent of fully autonomous coating systems, where AI-powered robots, guided by advanced sensors and machine learning algorithms, apply coatings with unprecedented precision and efficiency, even in hazardous environments. The long-term vision includes the widespread adoption of "digital twins" for coated assets, allowing for real-time simulation and optimization of protective strategies throughout an asset's entire lifecycle.

Potential applications on the horizon are vast, ranging from self-healing coatings for critical infrastructure in extreme environments to adaptive coatings for aerospace components that can change properties based on flight conditions. Challenges that need to be addressed include the standardization of data collection for AI training, ensuring the robustness and explainability of AI models, and developing cost-effective deployment strategies for MSMEs. Experts predict a future where materials themselves become "intelligent," capable of self-diagnosis and self-repair, driven by embedded AI, fundamentally altering how industries approach material degradation and protection.

A New Era of Industrial Resilience

The workshop on Corrosion and Wear Resistant Coating Technology for MSMEs, illuminated by the pervasive influence of AI, marks a significant moment in the evolution of industrial resilience. The key takeaway is clear: AI is not just an adjunct to coating technology but an integral, transformative force, promising unprecedented levels of durability, efficiency, and sustainability. This development is not merely an incremental improvement; it represents a foundational shift in how industries will protect their assets, moving from reactive maintenance to proactive, intelligent preservation.

Its significance in AI history lies in demonstrating AI's capability to revitalize and revolutionize even the most traditional industrial sectors, proving its versatility beyond software and digital services. The long-term impact will be felt in reduced global resource consumption, enhanced industrial safety, and a more level playing field for MSMEs. In the coming weeks and months, industry watchers should keenly observe further announcements regarding AI-driven coating solutions, partnerships between material science firms and AI developers, and the adoption rates of these advanced technologies within the MSME sector. The future of industrial protection is intelligent, adaptive, and AI-powered.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.