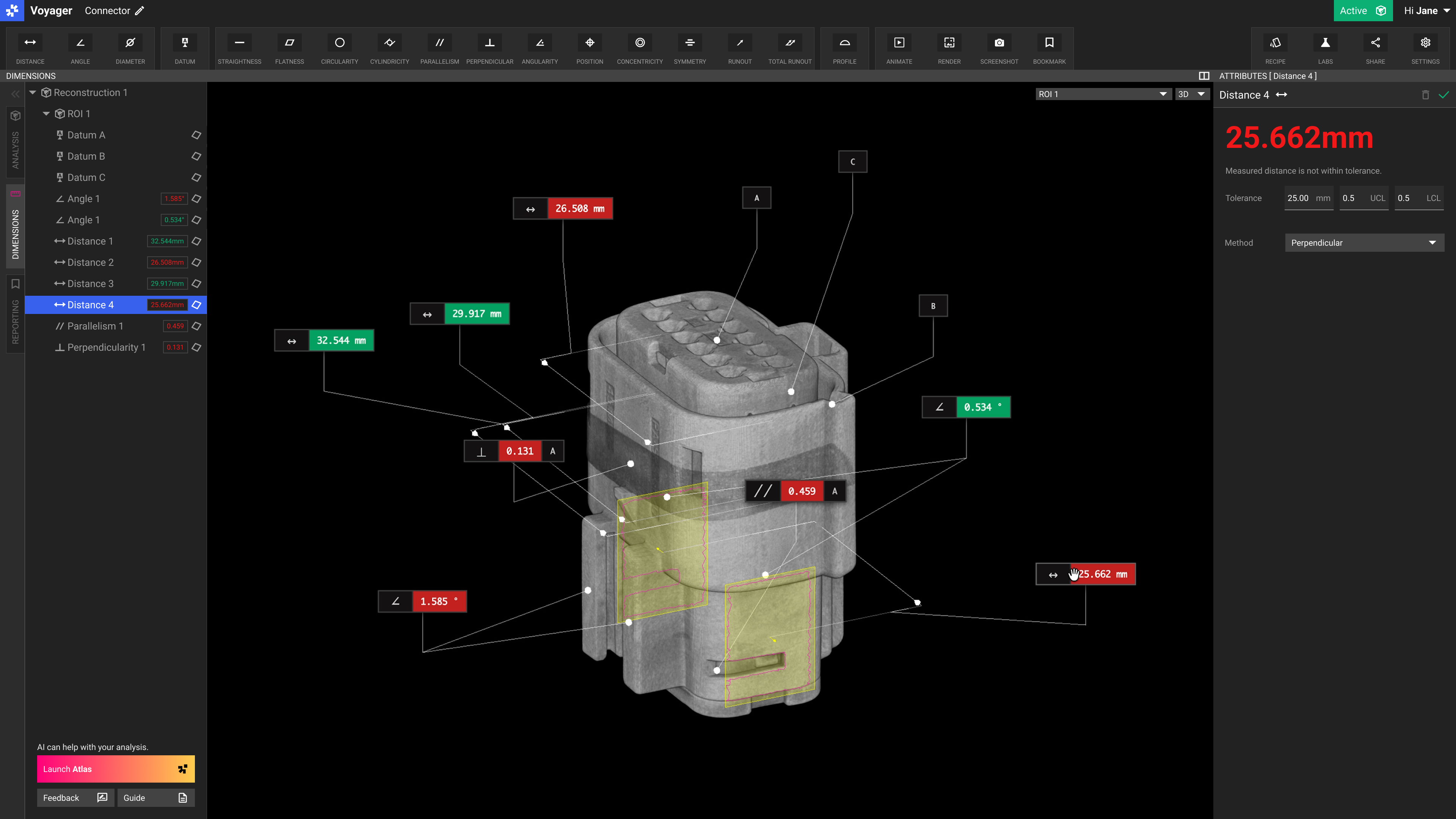

CAMBRIDGE, Mass., Oct. 29, 2025 (GLOBE NEWSWIRE) -- Lumafield, the leader in industrial X-ray CT technology, today announced Auto-Dimensioning, a robust new capability that provides engineers with easy, automated methods for Geometric Dimensioning and Tolerancing (GD&T). By delivering NIST-traceable measurements directly within its CT platform, Lumafield provides engineers with metrology-grade accuracy and fast, efficient dimensional workflows without the complexity or limitations of traditional inspection tools.

Historically, engineers focused on manufacturing, quality, and design have struggled to inspect complex internal geometries, delicate features, and transparent materials. Existing solutions such as coordinate measuring machines (CMM) and optical measuring machines (OMM) are slow, labor-intensive, and cannot access internal features in complex parts and assemblies.

With Auto-Dimensioning, Lumafield’s CT scanning technology now recognizes geometric features and measures geometric and dimensional tolerances such as flatness, parallelism, and profiles. The system automatically extracts internal and external dimensions from a single, non-destructive scan. Auto-Dimensioning builds on Lumafield’s new NIST-traceable calibration process, a workflow that uses a reference artifact with a documented calibration chain. Lumafield’s new calibration process ensures consistent, repeatable accuracy across every scanner and every site, giving engineers the confidence of NIST-traceability in a seamless, automated workflow.

As a result, measurement tasks that previously took hours with a CMM or OMM are reduced to a matter of seconds.

Key benefits of Auto-Dimensioning include:

- Faster dimensional inspections: Simple, intuitive verification of geometric and dimensional tolerances in a fraction of the time that it would take with a CMM and minimal fixturing.

- Greater coverage: Measure internal and complex external geometries such as overhangs in a single scan to inspect a wide range of features.

- Broader material capability: Accurately measure clear, reflective, and soft materials that OMMs and CMMs cannot.

- Confidence and accuracy: Powered by a NIST-traceable calibration workflow, Auto-Dimensioning delivers high accuracy, highly repeatable measurements.

“Auto-Dimensioning turns CT scanning into a true metrology tool, making it accessible to every engineer,” said Andreas Bastian, Co-Founder and Head of Product at Lumafield. “By automatically identifying and measuring features inside and out, we’re giving teams reliable, traceable data they can use to move faster, catch problems earlier, and build better products.”

Now in private beta, the capability will be generally available as part of Lumafield’s Voyager software in the first quarter of 2026.

About Lumafield

Lumafield gives engineers the power to see inside their work in unprecedented detail, at every stage of the product development process. Lumafield's industrial X-ray CT scanners are ideal for both lab-scale and in-line inspection, and its cloud-based analysis software delivers actionable insights immediately. Lumafield's technology has transformed both product development and high-volume manufacturing in industries as diverse as medical devices, athletic equipment, electronics, and consumer packaging.

Founded in 2019 and headquartered in Cambridge, Mass., with additional offices in San Francisco and Los Angeles, Lumafield has received funding from investors including IVP, Spark Capital, DCVC, Kleiner Perkins, Lux Capital, Tony Fadell's Build Collective, and Figma founder Dylan Field.

Learn more at Lumafield.com.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/b7eedb13-da0d-4d4a-844a-1002ef303b75

Media Contact Email press@lumafield.com for interviews or additional assets.