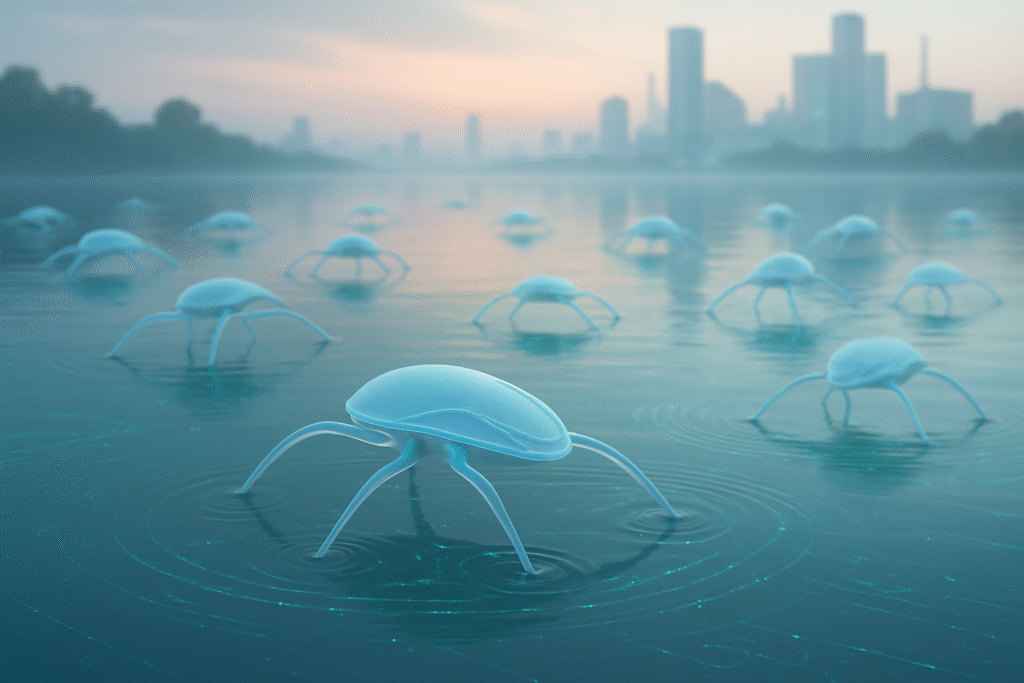

In a groundbreaking advancement that promises to redefine the capabilities of autonomous systems, engineers at the University of Virginia have unveiled HydroSpread, an innovative fabrication method for creating ultrathin soft robots capable of navigating aquatic environments with unprecedented agility. This breakthrough, poised to revolutionize fields from environmental monitoring to search and rescue, marks a significant leap in soft robotics by enabling the reliable and precise manufacturing of delicate, resilient machines directly on the surface of water. HydroSpread's ingenious approach bypasses the traditional pitfalls of soft robot fabrication, paving the way for a new generation of aquatic explorers.

The immediate significance of HydroSpread lies in its ability to produce highly functional, ultrathin robots that mimic the effortless locomotion of water-walking insects. By eliminating the fragile transfer processes inherent in previous manufacturing techniques, this method dramatically increases the yield and reliability of these sensitive devices. This innovation is not merely an incremental improvement; it represents a paradigm shift in how soft robots are designed and deployed, offering a pathway to low-cost, disposable scouts that can delve into hazardous or inaccessible aquatic zones, providing critical data and assistance where human intervention is challenging.

The Liquid Workbench: A Technical Deep Dive into HydroSpread's Innovation

At the heart of the HydroSpread method is a deceptively simple yet profoundly effective technique: utilizing water itself as the primary fabrication platform. This "liquid workbench" approach involves depositing liquid polymer ink onto a water bath, where surface tension and other natural forces cause the polymer to spread spontaneously and uniformly. The result is the formation of ultrathin films, some as fine as 100 micrometers—thinner than a human hair—which are then cured, typically with ultraviolet light, and precisely laser-cut into intricate shapes directly on the water's surface. This direct-on-liquid fabrication eliminates the need for transferring fragile films from solid substrates, a process that historically led to tearing, wrinkling, and structural failures.

The technical prowess of HydroSpread is evident in its ability to enable robots that genuinely "walk on water." This is achieved through a combination of direct fabrication on a liquid surface, which ensures ultralow surface roughness crucial for buoyancy and surface tension interaction, and biomimicry. The robots' designs are inspired by water striders, incorporating elements like curved legs and hydrophobic coatings for enhanced stability. Their locomotion is often powered by heat-actuated bilayer films; these films consist of two layers that expand at different rates when heated, causing them to bend or buckle, generating the precise paddling or walking motions required for movement. Precision laser cutting directly on the water further refines these designs, creating functional mechanisms that mimic natural aquatic movements, with the water acting as a heat sink to prevent distortion during cutting.

This novel approach stands in stark contrast to previous soft robotics manufacturing methods, which often struggled with the delicate balance required to create functional, ultrathin structures. Traditional techniques involved fabricating films on rigid surfaces and then attempting to transfer them to water, a step fraught with high rates of failure. HydroSpread's innovation lies in bypassing this problematic transfer entirely, building the robot in situ on its operational medium. Initial reactions from the AI research community have been overwhelmingly positive, with experts highlighting the method's potential to unlock new possibilities in robot design, particularly for applications requiring extreme delicacy, flexibility, and interaction with fluid environments. The enhanced precision, scalability, and versatility offered by HydroSpread are seen as critical advancements that could accelerate the development of a wide range of soft robotic devices.

Industry Ripples: HydroSpread's Competitive Edge and Market Disruption

The advent of HydroSpread is poised to send significant ripples across the robotics and AI landscape, particularly within the burgeoning field of soft robotics and flexible electronics. While the technology is still emerging from academic research, its foundational innovation in fabrication promises to confer strategic advantages and potential disruptions for a range of companies.

Companies specializing in environmental technology stand to be among the earliest and most direct beneficiaries. Firms engaged in water quality monitoring, oceanography, and ecological data collection could leverage HydroSpread to develop entirely new lines of low-cost, disposable, and highly deployable robotic scouts. These miniature autonomous agents could offer a scalable and efficient alternative to current expensive equipment and labor-intensive human operations, providing real-time data on pollutants, harmful algal blooms, or microplastics. Similarly, robotics manufacturers with a focus on specialized soft robots, especially those designed for interaction with fluid or delicate environments, will find HydroSpread's precise and reliable fabrication process highly advantageous. While giants like Boston Dynamics (NASDAQ: BDX) are known for their rigid, dynamic robots, the future could see specialized divisions or startups embracing HydroSpread for novel aquatic or compliant robotic solutions.

The competitive implications for major AI labs and tech companies, while not immediately impacting their core software-centric AI offerings, lie in the realm of embodied AI and AI for sensing and control in dynamic, fluid environments. HydroSpread provides the hardware foundation for highly adaptable, physical AI agents. This could disrupt traditional environmental monitoring services, where large, expensive sensors and human-operated vehicles might be supplanted by swarms of HydroSpread-enabled autonomous robots. Furthermore, existing manufacturing processes for flexible electronics, often plagued by fragile transfer steps and high failure rates, could face obsolescence as HydroSpread offers a more direct, precise, and potentially cost-effective alternative. Companies that act as early adopters and integrate HydroSpread into their R&D could secure a significant first-mover advantage, differentiating themselves with highly adaptable, sustainable, and integrated robotic solutions that can operate where conventional rigid robots cannot. This strategic positioning could unlock entirely new product categories, from biologically inspired robots for medical applications to flexible circuits resilient to extreme environmental conditions.

A New Frontier for Embodied AI: Wider Significance and Ethical Considerations

HydroSpread's breakthrough extends far beyond mere fabrication, signaling a profound shift in the broader AI landscape, particularly in the realms of soft robotics and embodied AI. This method aligns perfectly with the growing trend of creating intelligent systems that are deeply integrated with their physical environment, moving away from rigid, metallic constructs towards pliable, adaptive machines inspired by nature. By simplifying the creation of delicate, water-interacting robots, HydroSpread makes it easier to design systems that can float, glide, and operate seamlessly within aquatic ecosystems, pushing the boundaries of what embodied AI can achieve. The biomimetic approach, drawing inspiration from water striders, underscores a broader trend in robotics to learn from and work in harmony with the natural world.

The impacts of this technology are potentially transformative. In environmental monitoring and protection, fleets of HydroSpread-fabricated robots could revolutionize data collection on water quality, pollutants, and microplastics, offering a scalable and cost-effective alternative to current methods. For search and rescue operations, especially in flood-affected disaster zones, these miniature, agile robots could scout dangerous areas and deliver sensors, significantly boosting response capabilities without endangering human lives. Furthermore, the ability to create ultrathin, flexible devices holds immense promise for medical innovation, from advanced wearable diagnostics and smart patches to implantable devices that integrate seamlessly with biological systems. This technology also contributes to the advancement of flexible electronics, enabling more resilient and adaptable devices for various applications.

However, with great potential come significant challenges and concerns. The current lab prototypes, while impressive, face hurdles regarding durability and autonomous power supply for widespread field deployment. Ensuring these ultrathin films can withstand diverse environmental conditions and operate independently for extended periods requires further research into robust power sources and materials. Navigation and autonomy in unpredictable aquatic environments also present a complex AI challenge, demanding sophisticated algorithms for obstacle avoidance and task execution. Scalability and cost-effectiveness for mass production remain critical questions, as does the environmental impact of deploying potentially thousands of polymer-based devices; questions of biodegradability and recovery methods will need careful consideration. Finally, as with any pervasive sensing technology, ethical considerations surrounding surveillance, data privacy, and potential misuse of discrete monitoring capabilities will be paramount, requiring thoughtful regulation and public discourse.

The Horizon of HydroSpread: From Lab to Ubiquitous Aquatic AI

The trajectory of HydroSpread soft robotics is poised for rapid evolution, moving from laboratory-dependent prototypes towards autonomous, widely deployable devices. In the near term, research will intensely focus on integrating compact, onboard power sources, moving beyond external infrared heaters to solutions responsive to sunlight, magnetic fields, or tiny embedded heaters. This will be coupled with efforts to enhance autonomy through embedded sensors and sophisticated control systems, enabling robots to operate independently. Improving speed and responsiveness by optimizing heating and cooling cycles will also be crucial for efficient navigation in real-world scenarios, alongside refining fabrication precision to ensure consistent, high-quality, and reproducible devices.

Looking further ahead, the long-term developments for HydroSpread promise to unlock advanced functionalities and widespread deployment. The inherent simplicity of the method suggests significant potential for mass production and scalability, paving the way for the deployment of vast swarms of micro-robots capable of collaborative tasks like comprehensive environmental mapping or large-scale disaster response. Advanced AI integration will be paramount for autonomous navigation, complex decision-making, and executing intricate tasks in unpredictable environments. Concurrently, efforts will be directed towards significantly enhancing the durability and resilience of these ultrathin films to withstand the rigors of diverse real-world conditions.

The potential applications and use cases on the horizon are vast and impactful. HydroSpread robots could become ubiquitous in environmental monitoring, serving as autonomous sensors to track pollutants, map water quality, and detect harmful algal blooms or microplastics across vast aquatic bodies. In search and rescue operations, they could scout flooded zones or deliver sensors to dangerous areas, significantly boosting response capabilities. The biomedical field stands to gain immensely, with the promise of next-generation wearable medical sensors that conform seamlessly to the skin, advanced prosthetics, targeted drug-delivery systems, and even future implantable devices. Beyond robotics, HydroSpread could revolutionize flexible electronics and materials science, leading to bendable displays, smart patches, and novel sensors capable of operating in wet or dynamic conditions.

Despite this immense potential, several challenges must be overcome. The current dependence on external power is a significant hurdle, necessitating efficient onboard power solutions. Long-term durability in harsh natural environments remains a key area for improvement. Achieving complex actuation and precise navigation in dynamic aquatic settings will require integrating more sophisticated sensors and control algorithms. Furthermore, scaling production for commercial viability will demand addressing cost-effectiveness, reproducibility, and ensuring consistent performance across millions of units, alongside careful consideration of the environmental impact of widespread polymer deployment. Experts are, however, overwhelmingly optimistic, predicting that HydroSpread will "accelerate the development of autonomous sensors" and usher in a "paradigm shift in materials science," making the future of soft robotics "buoyant indeed." They foresee HydroSpread as a crucial pathway toward creating practical, durable, and flexible robots capable of operating effectively where traditional rigid machines fail.

Conclusion: A New Era for Aquatic Robotics and Embodied AI

The HydroSpread fabrication method represents a pivotal moment in the evolution of soft robotics and embodied AI. By enabling the precise, reliable, and scalable creation of ultrathin, water-walking robots, it fundamentally expands the capabilities of autonomous systems in aquatic and delicate environments. The key takeaways from this breakthrough are its innovative use of water as a manufacturing platform, its potential to democratize environmental monitoring, enhance disaster response, and drive advancements in flexible electronics and biomedical devices.

This development holds significant historical importance in AI, not as a direct algorithmic breakthrough, but as a foundational enabling technology. Much like advanced microchip fabrication paved the way for powerful computational AI, HydroSpread provides the physical substrate for a new generation of intelligent agents that can interact with the real world in ways previously unimaginable for rigid robots. It underscores a broader trend towards bio-inspired design and the integration of AI with highly adaptable physical forms.

In the coming weeks and months, the focus will undoubtedly remain on addressing the critical challenges of power autonomy, real-world durability, and advanced navigation. As researchers continue to refine the HydroSpread method and explore its myriad applications, the world will be watching to see how these miniature, water-walking robots begin to transform our understanding and interaction with our planet's most vital resource. This innovation promises to make the future of soft robotics and environmentally integrated AI not just intelligent, but truly buoyant.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.