Exploring the Production and Selection of Long Weld Neck Flanges

In the world of industrial piping systems, the Long Weld Neck Flange (LWN flange) stands out for its durability and precision. Known for its extended neck design, this specialized pipe flange is widely used in high-pressure and high-temperature applications such as refineries, power plants, and offshore engineering. As a trusted supplier, C.Z.IT DEVELOPMENT CO., LTD provides a wide range of solutions in stainless steel flanges, carbon steel flanges, and other customized products.

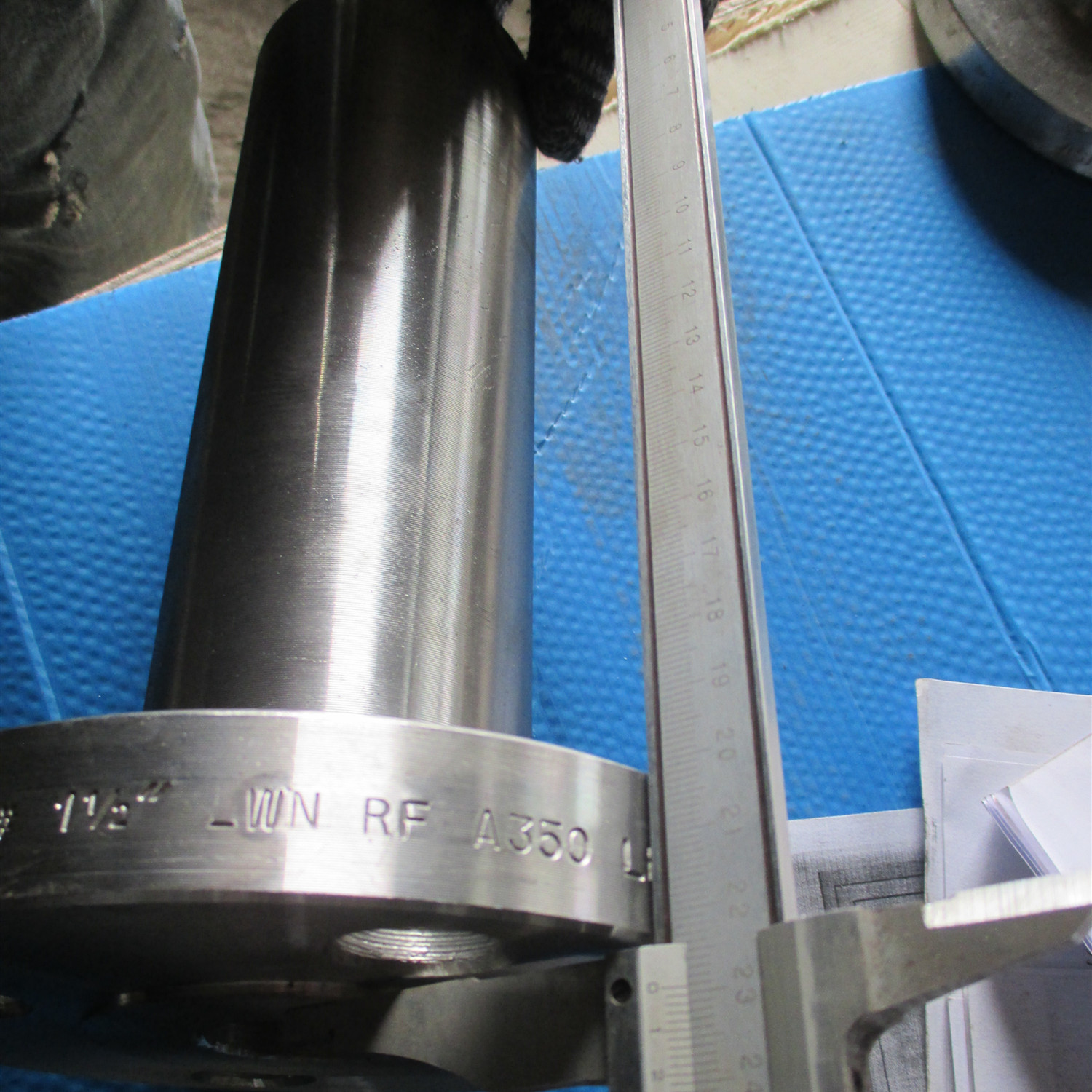

The production process of a Long Weld Neck Flange begins with high-quality raw materials, typically carbon steel, stainless steel, or alloy steel. Forging is the most common method, ensuring the flange of pipe achieves superior strength and uniformity. Once forged, the flange undergoes precision machining to maintain accurate dimensions and surface finishes. Heat treatment is also applied to enhance mechanical properties, making the flange suitable for critical industrial conditions.

A key feature of the LWN flange lies in its extended hub, which provides a smooth transition between the pipe and the flange, minimizing stress concentration. This design reduces the risk of fatigue and cracking, particularly under continuous pressure or thermal cycling. Manufacturers like C.Z.IT DEVELOPMENT CO., LTD follow strict international standards to ensure that every steel flange or stainless pipe flange meets rigorous performance requirements.

When selecting a Long Weld Neck Flange, buyers must consider factors such as material grade, pressure rating, size, and compatibility with existing piping systems. For example, ss pipe flanges are favored in corrosive environments, while carbon steel flanges are preferred for cost-effective, heavy-duty applications. Choosing the right flange of pipe not only ensures long-term reliability but also reduces maintenance costs over the service life of the equipment.

For industries that demand precision and durability, Long Weld Neck Flanges remain a reliable choice. By sourcing from experienced manufacturers such as C.Z.IT DEVELOPMENT CO., LTD, buyers gain access to high-quality pipe flanges engineered for performance and safety. Whether it is a stainless steel flange for chemical processing or a carbon steel flange for power generation, making the right selection is crucial to the success of any piping project.

Media Contact

Company Name: C. Z. IT DEVELOPMENT CO., LTD

Email: Send Email

Phone: +8613502159013

Address:1134-Huangying Builing Center Avenue, Tianjin Free Trade Zone (Airport Economic Zone)

City: Tianjin

Country: China

Website: https://www.czitgroup.com/

More News

View More

Recent Quotes

View More

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.