Marotta Controls Now Offers a Cryogenic Test Stand for Pressurized, Pneumatic System Space Components

New Liquid Helium Open Top, Dewar-fed System Enables Aerospace and Defense Customers to “Test Like They Fly” at Near Absolute Zero Temperature

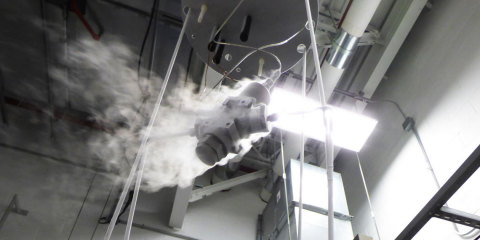

Marotta Controls, a rapidly growing aerospace and defense supplier with a 65-year-plus heritage in spaceflight, today announced it now houses at its New Jersey facility a new cryogenic test stand capable of testing pressurized components used in spacecraft. The test apparatus is an open top or magnet dewar system that uses liquid helium to achieve temperatures lower than -450°F (-232°C) or near absolute zero to simulate the environmental flight conditions found in space. Marotta will use the test stand to evaluate its space-grade pneumatic valves up to 16 inches in diameter, delivering on its commitment to simplify and speed development and delivery of components to customers.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20211117005281/en/

Aerospace and defense supplier Marotta Controls' new cryogenic test stand evaluates pneumatic valves and other space-grade components at near absolute zero temperature. (Photo: Business Wire)

The installation of the new test stand follows a series of dedicated initiatives driven by Marotta to serve the growing commercial spaceflight market. In 2020, the company introduced its first set of CoRe® solenoid valves for cryogenic temperatures. The CoRe Flow Controls series is a portfolio of 13 high performance solenoid valves designed for complex commercial launch vehicles and stands as one of the only valve catalogs available for space vehicles.

Notably, the storage dewar used in the new test stand has a usable volume of 300 cubic inches, making it an optimal container size for large cryogenic components—an important future-proofing feature as Marotta looks to expand its valve offerings to include larger rocket engine components.

“We have a history of taking our designs from conception through to testing under our own roof as we feel this is the best way to ensure quality and ROI for our customers,” said Brian Ippolitto, Director, Aerospace Systems Engineering, Marotta Controls. “And now, with the cryogenic test stand, we can validate and verify any and all flight-critical components so customers can test like they fly. We continue to invest in this dynamic market to ensure we meet current customer needs while positioning ourselves for future program developments.”

The test stand can be used to collect data for design validation during development and qualification testing process or as part of environmental stress screening of production units for verification of assembly workmanship.

How It Works

Valves being tested are affixed to the dewar’s lid and lowered into the dewar itself via crane. After a liquid nitrogen pre-chill, the liquid nitrogen is evacuated, and liquid helium is then piped into the dewar to submerge the valve in fluids reaching near absolute zero. Under atmospheric pressure, liquid helium reaches roughly -452°F (-268°C) and is the only substance to remain liquid at that temperature. It is a safer alternative for testing the performance of valves handing liquid hydrogen, which can reach -423°F (-252°C).

Once stabilized at the target temperature, the valve is loaded with up to 6,000 psig of gaseous helium (GHe). The valve is then tested for internal and external leakage, response time, and other performance characteristics.

The new test stand can also be used to test larger valves in liquid nitrogen at -320°F (-195°C). This method is a safer alternative for testing the performance of valves in liquid oxygen, which can reach -297°F (-182°C).

For more information, visit Marotta’s Cryogenic Valve page.

About Marotta Controls

Founded in 1943, Marotta Controls is a fully integrated solutions provider which designs, develops, qualifies and manufactures innovative systems and sub-systems for the aerospace and defense sectors. Our portfolio includes pressure, power, motion, fluid, and electronic controls for tactical systems, shipboard and sub-sea applications, satellites, launch vehicles, and aircraft systems. With over 200 patents, Marotta Controls continues to build on its legacy as a highly respected, family-owned small business based in the state of New Jersey. Twitter: @marottacontrols LinkedIn: Marotta Controls, Inc.

View source version on businesswire.com: https://www.businesswire.com/news/home/20211117005281/en/

#MarottaControls' new #cryogenic #teststand uses a large volume #liquidhelium #dewar system to evaluate #space-grade #rocket engine components at #nearzero temperature. #pneumaticvalves #solenoidvalves #spacevehicles #aerospace #defense #engineering

Contacts

Heather Ailara

211 Communications

+1.973.567.6040

heather@211comms.com

Katee Glass

Marotta Controls, Inc.

kglass@marotta.com

More News

View More

Recent Quotes

View More

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.