Marotta Controls Adds Additive Manufacturing to Expanding List of Capabilities

Aerospace and Defense Supplier Uses Patented Method to Produce 3D-printed Manifold Valve

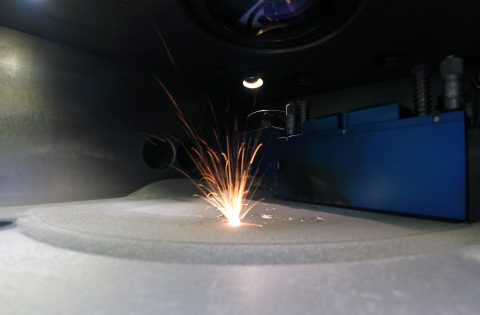

Marotta Controls, a rapidly growing aerospace and defense supplier based in New Jersey, today announced the successful integration of additive manufacturing (AM) into its portfolio of services. The company validated the capability’s viability by using its now patented method to create internal features of an advanced manifold valve. The selective laser sintering (SLS) design technique generated nuanced radial passages in various geometries not possible to achieve via traditional machine boring methods. Given this, the new manifold valve delivered increased velocity pressure control.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20210622005303/en/

Aerospace and Defense supplier Marotta Controls leverages additive manufacturing to increase product performance, first applying a patented design method to manifold valves. (Photo: Business Wire)

Marotta also confirmed that it is incorporating AM to reduce parts, simplify assembly and shorten lead times to deliver lower cost, higher performing products.

“We have a near 80-year culture of creative thinking, of challenging the status quo,” said Brian Fly, Vice President Marine Systems, Marotta Controls. “And we’re proud to confirm that that mindset resulted in a remarkable evolution to a tried and true part used for generations. Additive manufacturing offers some very interesting opportunities that we’re inherently designed to embrace on behalf of our customers. We anticipate more unique, disruptive innovations to come out of this capability as we continue to apply it.”

Additive manufacturing has long been touted across many industries as a smart way to accelerate the supply chain, initially used as a rapid tooling solution for custom injection mold creation and the like. Notably, a 2020 market report by Mordor Intelligence forecasted that the aerospace and defense market’s use of 3D printing will experience a 20 percent CAGR by 2025. This trend will only likely increase as military standards continue to adapt not just to the manufacturing process itself, but to the use of the necessary composite materials, too.

Proof of Concept: The Manifold Valve

Marotta Controls first came into existence troubleshooting valve designs that, despite being accepted as proven parts, continued to leak in end applications. The company ultimately fixed these issue and others, establishing itself as a go-to engineering shop capable of solving difficult problems. Which is why the company took on the challenge of improving the manifold’s performance in high pressure applications—a problem that required re-evaluating how and where best to apply Bernoulli’s equation within the system’s design.

Early manifold iterations saw performance increases driven by the introduction of new materials, chamber reconfigurations, and other mechanical adaptations. These solutions launched new product lines for Marotta that were customizable to a wide range of standards for military as well as commercial applications. However, the company still saw additional areas for innovation.

Valves and manifolds are historically produced via subtractive machining, with boring tools removing unwanted material to construct their radial passages within a single metal block. The radial passages are typically cylindrical or slightly frustoconical in nature. This design approach allows for passages that expand in two dimensions. By introducing a third dimension through AM, however, Marotta has improved those passage features to achieve desired performance.

Marotta’s patented approach starts with a 3D CAD model of choice that can meet varying ranges of end application specifications. Via the SLS machine, powdered metal is fused together layer by layer to construct a solid, single-pieced component with three-dimensional passage structures that can vary in shape—diamond, horizontal dome, spindle, branch-like, and others.

Marotta has evaluated its 3D valve concept in more than a dozen design configurations, with the passage structures varying. Velocity improvements are notable as is the part’s impact on the overall manifold’s production and performance.

For more information on how Marotta can help solve design challenges, visit www.marotta.com.

About Marotta Controls

Founded in 1943, Marotta Controls is a fully-integrated solutions provider which designs, develops, qualifies and manufactures innovative systems and sub-systems for the aerospace and defense sectors. Our portfolio includes pressure, power, motion, fluid, and electronic controls for tactical systems, shipboard and sub-sea applications, satellites, launch vehicles, and aircraft systems. With over 200 patents, Marotta Controls continues to build on its legacy as a highly respected, family-owned small business based in the state of New Jersey. Twitter: @marottacontrols LinkedIn: Marotta Controls, Inc.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210622005303/en/

#MarottaControls now using additive manufacturing to produce higher performing products faster and more cost efficiently. #Aerospace & #defense supplier demonstrates capabilities with #patented #3Dprinted design for #ManifoldValves. #3Dprinting #valves

Contacts

Heather Ailara

211 Communications

+1.973.567.6040

heather@211comms.com

Katee Glass

Marotta Controls, Inc.

kglass@marotta.com

More News

View More

Recent Quotes

View More

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.