Goldenlaser Introduces Laser Cutting Solutions for Premium Quality Filter Cloth

In today's world, filtration has become necessary in human production and life due to environmental pollution caused by economic and social development. The separation of insoluble substances from a fluid by passing it through a porous material is called filtration.

The filtration market is one of the fastest growing segments of the nonwovens industry. Increasing consumer demand for clean air and drinking water, as well as increasingly stringent regulations worldwide, are the key growth drivers for the filtration market. Manufacturers of filtration media are focusing on new product development, investment and growth in new markets to stay ahead of the curve in this important nonwovens segment.

The separation of solids from liquids or gases by means of textile filtration media is an essential part of countless industrial processes, contributing to increased product purity, energy savings, process efficiency, recovery of valuable materials and overall improved pollution control. The complex structure and thickness of textile materials, especially woven and non-woven, lend themselves to filtration.

Filter cloth is the medium where the filtration really takes place. The filter cloth is mounted on the depleted surface of the filter plate. As the slurry nourishes in the filter plate chamber, the slurry is filtered through the filter cloth. The main filter cloth products on the market today are woven and non-woven (felt) filter cloth. Most filter cloths are made from synthetic fibres such as polyester, polyamide (nylon), polypropylene, polyethylene, PTFE (teflon), as well as natural fabrics such as cotton. Filter cloth as an important filter medium is widely used in mining, coal, metallurgy, chemical industry, food processing and other related industries that require solid-liquid separation.

The quality of the filter cloth is key to improving the operation of the filter press. In order to guarantee the quality of the filter cloth, surface quality, attachment and shape are crucial factors. Quality filter media providers investigate each customer's industry and application in depth so that they can tailor the filter cloth to the demanding needs of each customer, from natural materials to synthetic and felt materials.

More and more filter media manufacturers have realized that ensuring a quick response turnaround is the most satisfying for their customers. They work with trusted suppliers close to the assembly area to ensure they can supply the filter cloth required for a specific application. To achieve this, many filter fabric manufacturers have invested in best-in-class laser cutting machines from goldenlaser. Here, precise fabric shapes are created by CAD programming and exchanged to a fast laser cutting machine to ensure accuracy, speed and definitive in quality.

CO2 flatbed laser cutting machine from goldenlaser

Cutting filter materials with Co2 laser cutting machine from goldenlaser

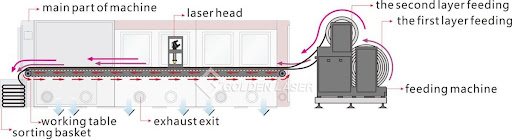

The goldenlaser model JMCCJG-350400LD large format CO2 laser cutting machine has been specially developed for high speed and high precision cutting of industrial filter fabrics. This laser cutting system offers considerable advantages in the processing of filtered materials. Fully enclosed construction with a table size (length by width) of 3,500 x 4,000 mm. Rack and pinion double drive construction for high speed and high acceleration as well as high precision.

Continuous and automatic processing using a conveyor system combined with a feeding device to handle the material from the roll. The matching unwinding device also allows cutting in double fabric layers.

In addition, the thermal laser process ensures that the edges are sealed when cutting synthetic textiles, thus preventing fraying, which makes subsequent processing easier. The laser also enables the processing of fine details and the cutting of small micro-perforations that cannot be produced by knives. In order to gain greater flexibility, there is space for additional marking modules next to the laser to facilitate the subsequent sewing process.

Media Contact

Company Name: Goldenlaser

Contact Person: Sales

Email: Send Email

Country: China

Website: https://www.goldenlaser.cc/

More News

View More

Recent Quotes

View More

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.