Extruder Gearbox Repair Experts Share 5 Key Warning Signs of Industrial Gearbox Failure

Tampa, FL - February 25, 2025 - Leading experts in industrial gearbox repair are sharing their knowledge of the common warning signals of gearbox failure allowing businesses to extend the lifetime of their equipment and reduce expensive downtime. Having years of experience maintaining and repairing industrial gearboxes in many various industrial sectors such as the oil and mining industry, steel mills, nuclear plants, water and power plants. It’s important to be aware of the five key indicators your gearbox needs repair.

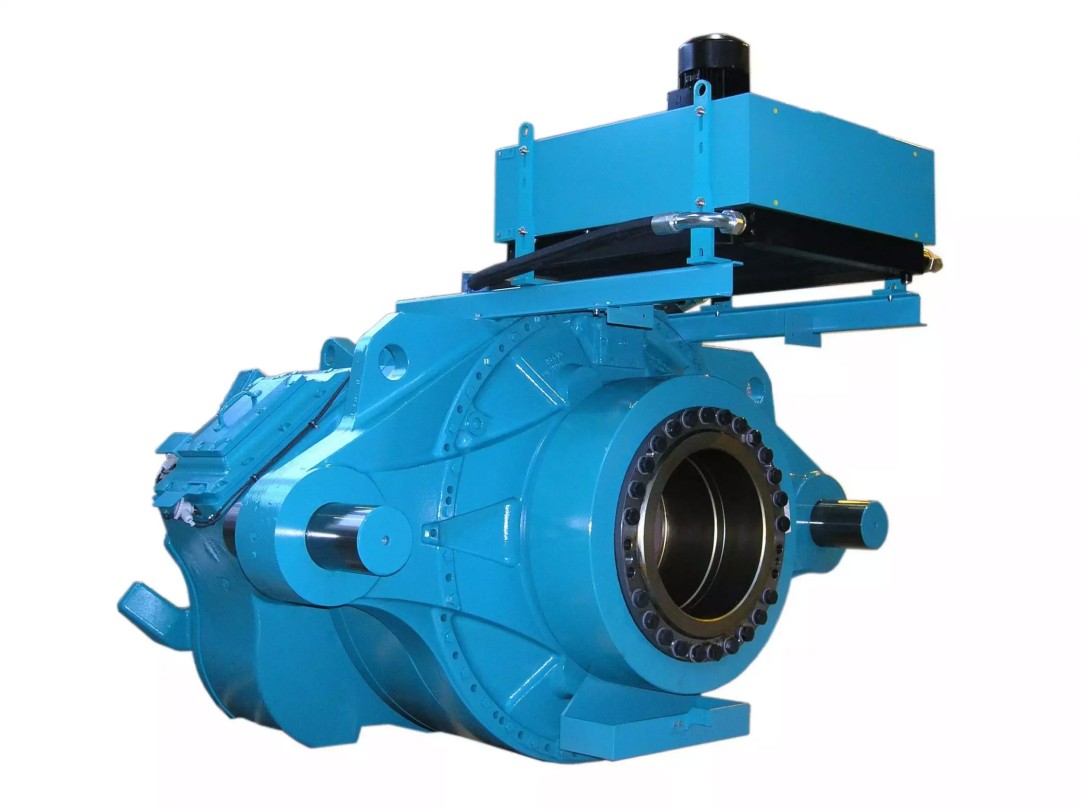

From food production and plastics to chemical and pharmaceutical applications, extruder gearboxes are rather important in manufacturing and processing industries. A gearbox breaking-down can lead to unexpected down time, lost in revenue and costly repairs. Early gearbox failure warning signs let businesses act preventatively to maintain reliable operations.

5 Important Signs of Gearbox Failure:

Unusual sounds and vibrations could indicate gear wear, damaged bearings, or misalignment from too loud or vibrational sources.

High running temperatures indicate either too much friction or insufficient lubrication, both of which could cause catastrophic failure.

Oil leaks or contamination can point to internal wear and in the absence of correction, gear failure from contaminated or leaking lubrication.

Wearing out gears or mechanical inefficiencies can reduce operational efficiency, therefore causing torque loss.

Burning Smells or Smoke – A serious red flag that your gearbox is overheating or on the verge of failure.

"Preventing expensive gearbox failures depends fundamentally on regular inspections and timely maintenance," said Matthew Clark, Owner at Extruder Gearbox Repair. Early identification of these warning signals can enable businesses to repair or rebuild gearboxes before major issues start, therefore saving time and money.

To help companies retain their extruder gearboxes, Extruder Gearbox Repair offers seasoned diagnosis, repairs, and maintenance solutions suited to each operating demand.

Location: 2209 N 40th St, Tampa, FL 33605

Media Contact

Company Name: Extruder Gearbox Repair

Contact Person: Albert Mesa

Email: Send Email

Phone: 813-737-7320

Address:2209 N 40th St

City: Tampa

State: FL 33605

Country: United States

Website: https://extrudergearbox.net

More News

View More

Recent Quotes

View MoreQuotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.