$7 Billion Annual Potential from New Strategic Agreement to Commercialize Self-Contained Pyrolysis Waste-to-Energy Units in California: China New Energy Group Company (Symbol: CNER)

- New Technologies and Innovations for Scalable, Clean Energy Solutions Focused on Modular Carbon-Negative Waste to Energy Projects.

- Syngas BioEnergy bioReactor is a Fully Self-Contained Pyrolysis Waste-to-Energy Unit Engineered Inside a Standard 40-foot Shipping Container.

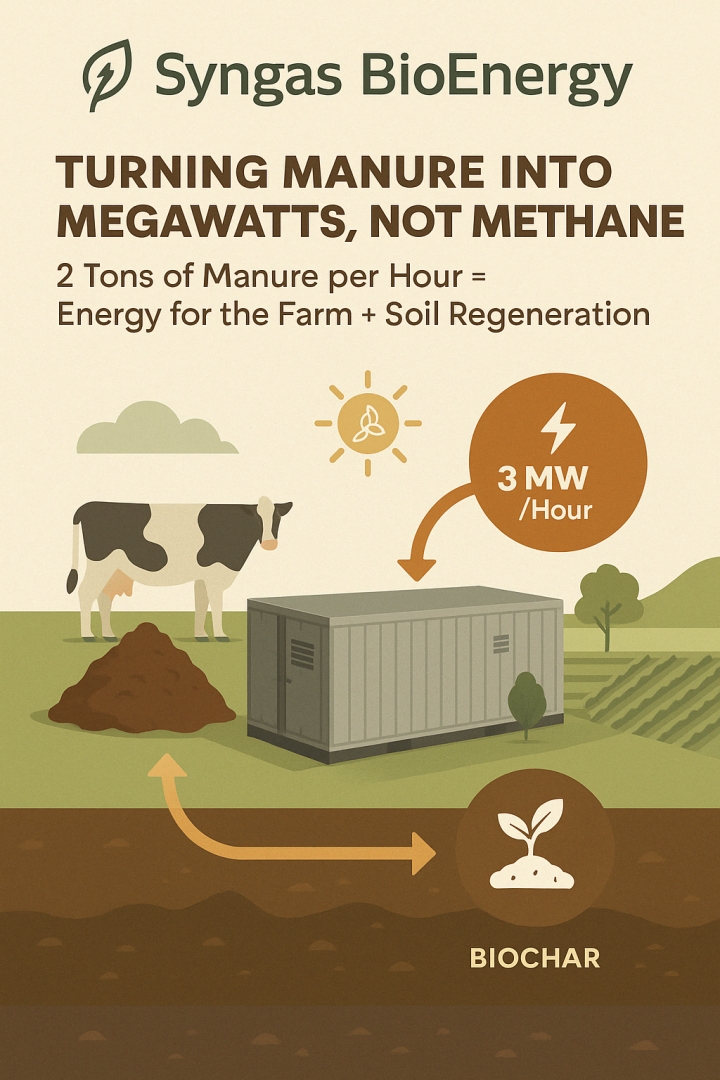

- Compact System Delivers up to 1.5 Megawatts of Thermal Energy Per Hour from 2 Tons Per Hour of Cow Manure.

- New Agreement to Commercialize Syngas bioEnergy Tech to Address Energy Security for Farmers and Ranchers Starting in the California Central Valley.

- Plans for Multiple Additional bioReactor Units to Serve Local Farming and Processing Operations that are Vulnerable to Grid Constraints and Price Volatility.

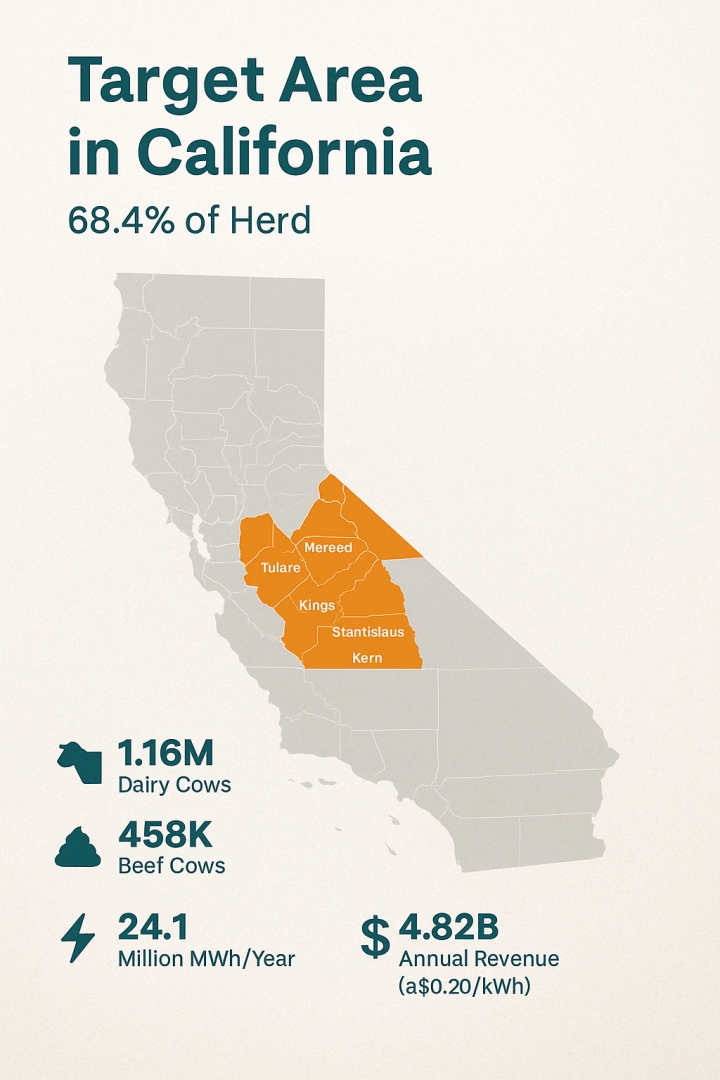

- Market Opportunity in California Alone is Substantial and Represents One of the World’s Largest and Most Concentrated Manure-to-Energy Markets.

- Converting Just 2 Tons of Manure into 1.5 MWh of Power Per Hour, Potential Energy Output Exceeds 35 million MWh Annually — An Estimated $7 Billion in Potential Annual Revenue.

China New Energy Group Company (OTC: CNER) commercializes new technologies and innovations that deliver scalable, clean energy solutions. CNER empowers agriculture, industry and remote operations with carbon-negative power, on-site waste processing and resilient energy infrastructure through capital investments in modular waste-to-energy technologies.

The Syngas BioEnergy bioReactor is a fully self-contained waste-to-energy unit engineered inside a standard 40-foot shipping container. Each reactor is prebuilt in the CNER factory, rigorously tested, and delivered ready for rapid deployment — making it one of the fastest, most portable solutions for on-site power generation. This rugged, modular design allows farms to scale energy production like building blocks, placing reactors exactly where waste is generated, without the need for complex construction or permitting delays. Whether deployed individually or as part of a 30-unit network, each CNER bioReactor acts as a decentralized energy module feeding the broader on-farm power grid — making speed, flexibility, and off-grid independence the defining features of our energy infrastructure solution.

The heart of the CNER system is the pyrolysis process — a high-temperature, low-oxygen thermal conversion that transforms organic waste into three valuable outputs. First, it produces syngas, a clean, combustible gas used to power generators and supply on-site energy. Second, it yields biochar, a carbon-rich solid that can be mixed with fresh manure to enhance its energy density and combustion efficiency in future cycles, creating a regenerative fuel loop. Third, it emits nutrient-rich gases and vapors ideal for feeding algae cultivation systems, which are harvested to produce organic fertilizer and high-protein feed for livestock. This closed-loop CNER process maximizes every molecule of waste, turning environmental liabilities into power, profit, and productivity.

Agreement to Commercialize Syngas bioEnergy Technology to Address Energy Security for Farmers and Ranchers.

On April 22nd CNER announced that it has entered into a strategic agreement to commercialize the syngas technology developed by BioEnergy Solutions Inc., an Alberta, Canada renewable energy developer, to launch the first commercial deployment of the bioReactor—a modular, containerized waste-to-energy system.

The initial installation is proposed to be located onsite at a major cattle operation in California’s San Joaquin Valley. Under the agreement, CNER will create a subsidiary called SynGas BioEnergy Corporation, the CNER internal commercialization entity. CNER will provide capital to fund the build, installation and ongoing operations of the CNER bioReactor technology.

The CNER bioreactor converts manure and other organic waste into clean thermal energy and biochar. The compact system delivers up to 1.5 megawatts of thermal energy per hour from 2 tons per hour of cow manure. The bioreactors will be placed close to waste sites, creating a micro-power Grid for all farming operations.

Manure pollution is one of California's most severe yet under-acknowledged environmental crises. With nearly 2.4 million cows (Source: USDA California Cattle County Estimates, May 9, 2022), the state produces almost 128,800 tons of manure daily,” said Gary Bartholomew, Chairman and CEO of CNER. “California represents a massive opportunity for scalable, on-site bioenergy solutions that solve waste, energy, and environmental issues in one closed-loop system.”

Following this first deployment, CNER plans to fund the rollout of multiple additional bioReactor units. Each installation will be designed to serve the energy demands of local farming and processing operations that are increasingly vulnerable to grid constraints and price volatility.

The market opportunity in California alone is substantial and represents one of the world’s largest and most concentrated manure-to-energy markets. With close to 2.4 million dairy and beef cows producing nearly 128,800 tons of manure per day (www.lpelc.org March 5, 2019). Under strict environmental regulations, this waste stream creates both a cost burden and an untapped energy resource.

With the CNER Syngas BioEnergy bioReactors converting just 2 tons of manure into 1.5 MWh of power per hour, the total potential energy output exceeds 35 million MWh annually — translating to an estimated $7.0 billion in potential annual energy revenue at $0.20 per kWh. Deploying approximately 2,683 CNER bioReactors statewide would unlock this market, giving California farmers energy independence, reducing emissions, and transforming a waste liability into clean, localized power.

For more information on $CNER visit: www.cner.us

DISCLAIMER: https://corporateads.com/disclaimer/

Disclosure listed on the CorporateAds website

Media Contact

Company Name: China New Energy Group Company

Contact Person: Gary Bartholomew, Chairman and CEO

Email: Send Email

Phone: +1 647-400-6927

Address:5428 South Regal St. Unit 30954

City: Spokane

State: Washington

Country: United States

Website: www.cner.us

More News

View More

Recent Quotes

View More

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.