Standard Lithium Successfully Commissions First Commercial-Scale DLE Column in North America

EL DORADO, Ark., April 24, 2024 (GLOBE NEWSWIRE) -- Standard Lithium Ltd. (“Standard Lithium” or the “Company”) (TSXV:SLI) (NYSE American:SLI) (FRA:S5L), a leading near-commercial lithium development company, is pleased to announce that it has successfully commissioned and validated the performance of the largest continuously-operating Direct Lithium Extraction (“DLE”) equipment in North America. The Company recently installed a commercial-scale DLE column at its Demonstration Plant near El Dorado, Arkansas. The column is a Li-ProTM Lithium Selective Sorption (“LSS”) unit, supplied by Koch Technology Solutions, LLC (“KTS”).

The column was installed and integrated into the Company’s existing Demonstration Plant, and is currently extracting lithium from Smackover Formation brine at an input flow rate of 90 gallons per minute (“gpm”; or 20.4 m3/hr). This is, to the best of the Company’s knowledge, both the largest DLE installation, and the only example of a commercial-scale DLE column in operation in North America. Since commissioning, the column has operated continuously and exceeded the design parameters for lithium recovery and rejection of impurities. Key technical highlights of the commercial-scale DLE column are provided below:

Key Findings:

- Lithium Recovery Efficiency: During a representative two-week period of performance in April 2024, the Li-ProTM LSS (DLE) process achieved an average lithium recovery (i.e. after loading and elution) of 97.3% from the 90 gpm incoming brine flow (the average incoming brine contained 208 mg/L lithium during the same period).

- Element Rejection Rate: During the same period, the DLE process rejected, on average, over 99% of the key contaminants sodium, calcium, magnesium and potassium from the brine (i.e. less than 1% of those contaminants made it through the DLE step into the first lithium chloride solution); and over 95% of boron was rejected.

- This high degree of contaminant rejection after DLE results in a substantially purified lithium chloride solution (the eluate). This eluate can then be further refined and concentrated using tested and proven steps to make it ready for conversion to either lithium carbonate or lithium hydroxide. These additional process steps have been successfully demonstrated for several years at the Company’s Demonstration Plant. In simple terms, when the DLE step rejects a higher percentage of impurities, the final lithium chloride solution, which is converted to battery-quality products, can be produced more efficiently.

- Operational Cycles: The most recent full-size commercial scale Li-ProTM LSS column has completed over 86 operational cycles, and the Li-ProTM LSS technology has completed over 8,500 operational cycles at the Demonstration Plant.

- Brine Processed: As of the end of March 2024, the Demonstration Plant had processed 17,039,825 gallons (64,495,738 litres) of Smackover brine, produced directly from the formation and reinjected continuously back into the same formation.

- Lithium Chloride: Since May 2020, the Demonstration Plant has produced many millions of gallons of ‘raw’ lithium chloride eluate from several generations of DLE technology development. Almost all of the ‘raw’ lithium chloride has been returned to the formation through LANXESS’ existing tail brine reinjection infrastructure. Additionally, over the last 4 years, approximately 330,000 gallons (1.25 million litres) of concentrated and/or purified lithium chloride solution have been produced for further process testing or for conversion into battery-quality lithium carbonate or hydroxide.

The performance of this commercial-scale DLE column is being used to validate the design assumptions for the Phase 1A Project and also underpins the process design work underway for the South West Arkansas (“SWA”) Project (see Press Release dated 24 January 2024).

Standard Lithium’s Director, President & COO, Dr. Andy Robinson commented: “Importantly, the column currently operating at SLI’s Demonstration Plant is identical to those that will be used in the commercial application, both in terms of the size, design and construction of the column, as well as the sorbent media being used inside. As such, this important collaboration between SLI and KTS at our Demonstration Plant is the first example in North America of DLE technology being deployed successfully using commercial-scale equipment. Validation of performance and successful operation of this column is a significant derisking step on our way to becoming the next major sustainable lithium producer in North America.”

Figure 1 – Upper and lower views of the Commercial-scale DLE column in operation at Standard Lithium’s Demonstration Plant near El Dorado, Arkansas.

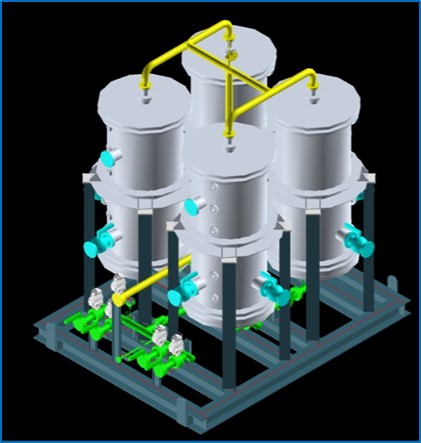

Figure 2 – Engineering design of commercial column configuration – SLI’s commercial facilities will use the same commercial-scale column, as currently being operated by SLI, in a four pack configuration; the commercial plants are expected to have multiple four packs.

About Standard Lithium Ltd.

Standard Lithium is a leading near-commercial lithium development company focused on the sustainable development of a portfolio of lithium-brine bearing properties in the United States. The Company prioritizes brine projects characterized by high-grade resources, robust infrastructure, skilled labor, and streamlined permitting. The Company aims to achieve sustainable, commercial-scale lithium production via the application of a scalable and fully-integrated Direct Lithium Extraction (“DLE”) and purification process. The Company’s signature projects, the Phase 1A Project and the South West Arkansas Project, are located on the Smackover Formation in southern Arkansas, a region with a longstanding and established brine processing industry. The Company has also identified a number of highly prospective lithium brine project areas in the Smackover Formation in East Texas and is conducting an extensive brine leasing program in the key project areas. In addition, the Company has an interest in certain mineral leases located in the Mojave Desert in San Bernardino County, California.

Standard Lithium trades on both the TSX Venture Exchange and the NYSE American under the symbol “SLI”; and on the Frankfurt Stock Exchange under the symbol “S5L”. Please visit the Company’s website at www.standardlithium.com.

About Koch Technology Solutions

KTS is the technology licensing business of KES. KTS creates value for its customers across a growing portfolio of technologies including direct lithium extraction, the polyester value chain, and 1,4-Butananediol plus its derivates. KTS combines its exclusive technologies, expertise, and capabilities with those of other KES companies to provide overall solutions to optimize customer’s capital investments and existing manufacturing assets.

Qualified Person

Marek Dworzanowski, EUR ING, CEng, HonFSAIMM, FIMMM, a qualified person as defined by National Instrument 43-101, and a Consulting Metallurgical Engineer who is independent of the Company, has reviewed and approved the relevant scientific and technical information in this news release.

Twitter: @standardlithium

LinkedIn: https://www.linkedin.com/company/standard-lithium/

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release. This news release may contain certain “Forward-Looking Statements” within the meaning of the United States Private Securities Litigation Reform Act of 1995 and applicable Canadian securities laws. When used in this news release, the words “anticipate”, “believe”, “estimate”, “expect”, “target, “plan”, “forecast”, “may”, “schedule” and other similar words or expressions identify forward-looking statements or information. These forward-looking statements or information may relate to intended development timelines, future prices of commodities, accuracy of mineral or resource exploration activity, reserves or resources, regulatory or government requirements or approvals, the reliability of third party information, continued access to mineral properties or infrastructure, fluctuations in the market for lithium and its derivatives, changes in exploration costs and government regulation in Canada and the United States, and other factors or information. Such statements represent the Company’s current views with respect to future events and are necessarily based upon a number of assumptions and estimates that, while considered reasonable by the Company, are inherently subject to significant business, economic, competitive, political and social risks, contingencies and uncertainties. Many factors, both known and unknown, could cause results, performance or achievements to be materially different from the results, performance or achievements that are or may be expressed or implied by such forward-looking statements. The Company does not intend, and does not assume any obligation, to update these forward-looking statements or information to reflect changes in assumptions or changes in circumstances or any other events affecting such statements and information other than as required by applicable laws, rules and regulations.

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/0bb83fab-7dfe-4a67-a291-b4b373716d3f

https://www.globenewswire.com/NewsRoom/AttachmentNg/c600c866-19f7-4ee9-9687-46c0bcb32763

Investor and Media Inquiries Allysa Howell Vice President, IR & Corporate Communications +1 720 484 1147 a.howell@standardlithium.com

More News

View More

Recent Quotes

View More

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.