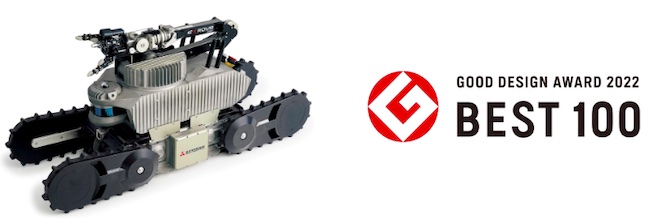

MHI Wins Best 100 Prize at Good Design Award 2022 for EX ROVR "ASCENT" Explosion-Proof Plant Patrol Inspection Robot

By:

JCN Newswire

October 07, 2022 at 13:51 PM EDT

TOKYO, Oct 7, 2022 - (JCN Newswire) - EX ROVR "ASCENT," the second-generation explosion-proof(1) plant patrol inspection robot produced by Mitsubishi Heavy Industries, Ltd. (MHI), has won the "Good Design Best 100" award in the "Good Design Award 2022"(2) hosted by the Japan Institute of Design Promotion. EX ROVR "ASCENT" is a robust and reliable partner to achieve a safe working environment, protecting workers and assets by autonomously inspecting plants that process oil, gas, and chemicals. In scenes of accidents, EX ROVR "ASCENT" can be used to report the status even in areas where humans cannot access.

|

Good Design Best 100 winners are selected as the top 100 entries among the Good Design Award 2022 winners, based on overall judgement of aesthetics, concept, and potential. The development of the EX ROVR series started after gas leakage accident in tunnels occurred in which on-site rescuers were unable to perform activities due to the existence of flammable gases. In winning this award, EX ROVR "ASCENT" was commended for its technology and design that packs many features in a compact body to achieve safety of workers and efficient asset management, the advanced fusion of IoT and robotics, while being Zone 1 explosion-proof.

Key features of EX ROVR "ASCENT" include superior mobility achieved by its tracked driving mechanism, long reach provided by its 6 degree-of-freedom wire-actuated manipulator, and domestic and overseas explosion-proof certification such as IECEx(3) and ATEX.(4) The robot can easily navigate staircases up to 46 degrees, steps of up to 20cm, and drive through rough terrains. The manipulator can be extended to a height of 1.5 meters, which allows close-up and front-facing inspection of pressure gauges, pipes, and other inspection targets.

Spurred on by this award, MHI will further improve EX ROVR "ASCENT" in terms of both hardware and software, and continue to offer solutions based on explosion-proof robot technology to realize safety and security in diverse environments such as refineries and industrial plants.

(1) Explosion-proof devices are defined as being equipped with features that collectively limit the danger of the device igniting an explosion or fire from its own electric sparks or heat in environments filled with inflammable gas. Devices for use in industrial plants, etc. should be certified as explosion-proof.

(2) As successor of the Good Design Product Selection System founded in 1957, the Good Design Award represents Japan's activities in design evaluation and promotion, with the "G mark" award symbol widely acclaimed as a mark of superior design. More details can be found at www.g-mark.org/

(3) IECEx certificates are issued by the International Electrotechnical Commission (IEC) and attest to the suitability of using the device in explosive atmospheres. IECEx certification, which is widely adopted internationally, is based on quality assessment standards set by the IEC.

(4) ATEX (ATmospheres EXplosibles) certification refers to two directives based on IECEx relating to explosive atmospheres and stipulate the health and safety requirements and conformity assessment procedures that must be met to bring devices or protective systems for use in explosive atmospheres to the EU market. As the ATEX directives and IECEx follow the same standards, there is fundamentally no difference in their technical details.

Please visit the [EX ROVR plant patrol inspection robot] product page at www.mhi.com/products/energy/ex_rovr.html.

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world's leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.com

More News

View More

Why Gold Loves Trump as Much as Trump Loves Gold ↗

November 26, 2025

Google's Gemini 3 Sends Broadcom Soaring: TPUs Take Center Stage ↗

November 26, 2025

Palantir Isn’t Just Riding the AI Boom—It’s Orchestrating It ↗

November 26, 2025

Insiders Are Snapping Up This AI Stock—Is a Big Bounce Coming? ↗

November 26, 2025

These 2 Energy Titans Just Scored Major Wins to Close Out November ↗

November 26, 2025

Via MarketBeat

Recent Quotes

View More

Stock Quote API & Stock News API supplied by www.cloudquote.io

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.

© 2025 FinancialContent. All rights reserved.

>