JAEA and MHI Commence Demonstration Program for Hydrogen Production Using a High Temperature Engineering Test Reactor

By:

JCN Newswire

April 28, 2022 at 02:04 AM EDT

|

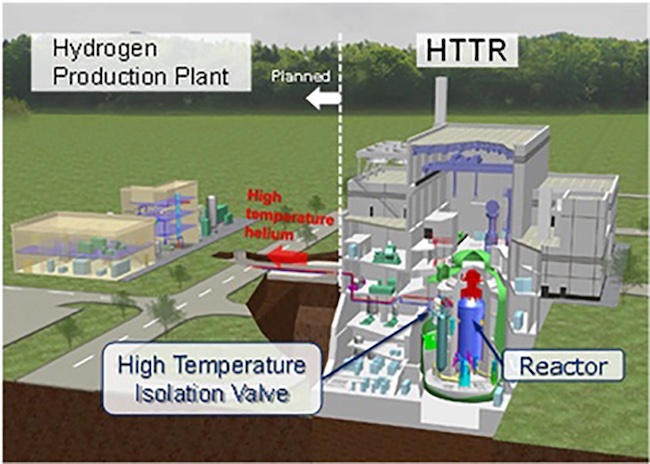

The Japan Atomic Energy Agency (JAEA), a national research and development agency, and Mitsubishi Heavy Industries, Ltd. (MHI), have been contracted by the Agency for Natural Resources and Energy, part of the Ministry of Economy, Trade and Industry (METI), to conduct its Hydrogen Production Demonstration Project Utilizing Very High Temperature, and from this fiscal year initiated a program to produce hydrogen using a High Temperature Engineering Test Reactor (HTTR). Under this program, a newly built hydrogen production plant will be connected to an HTTR owned by JAEA, with the aim of proving the technology for hydrogen production utilizing the high temperature heat obtained from the HTTR. The determination of specific renovations necessary to connect the hydrogen production plant, along with the licensing procedure, equipment modifications, and testing, will be conducted in stages. To support future advancements in technologies for hydrogen production, JAEA and MHI will also examine the feasibility of enlarging certain components to allow for large-scale hydrogen production (such as the high temperature isolation valve), and explore carbon-free hydrogen production technologies in combination with high temperature gas-cooled reactors.

Through this program, JAEA and MHI will prove the technology for hydrogen production utilizing extremely high temperature heat from sources such as high temperature gas-cooled reactors, and realize the stable, large-scale, carbon-free hydrogen production.

Supplementary Information

Governments and companies around the world are accelerating efforts to lower the cost of carbon-free hydrogen throughout the entire process, from production to use. Japan's Strategic Energy Plan (Cabinet approval in October 2021) sets as a policy the establishment of elemental technologies for hydrogen production using high temperature gas-cooled reactors. In addition, the Green Growth Strategy Through Achieving Carbon Neutrality in 2050 (formulated in June 2021) sets as a policy the development by 2030 of technologies necessary to produce large-scale, low cost, carbon-free hydrogen by utilizing HTTRs, which have achieved world record-high temperatures.

In accordance with these national policies, on February 8, 2022, the Agency for Natural Resources and Energy, part of the Ministry of Economy, Trade and Industry (METI), began accepting bids for its Hydrogen Production Demonstration Project Utilizing Very High Temperature. A consortium comprising JAEA, which is capable of conducting tests using an HTTR, and MHI, which is evaluating technology for hydrogen production using high temperature gas-cooled reactors, was selected as the consignee for this project.

For the first stage of this program, in fiscal 2022, JAEA and MHI will design an HTTR-Hydrogen Production Test Facility that connects an HTTR with a hydrogen production plant, and formulate a development plan for such equipment as high temperature isolation valves in preparation for a demonstration reactor. JAEA and MHI will also analyze technologies for carbon-free hydrogen production capable of using high temperature heat from high temperature gas-cooled reactors, and compare these technologies to determine hydrogen production methods with the potential to enhance the efficiency of hydrogen production.

For further information, see: bit.ly/3vTkz6p

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world's leading industrial groups, spanning energy, logistics & infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.com

More News

View More

Ozempic, Mounjaro, Wegovy, or Zepbound? This ETF Holds Them All ↗

January 19, 2026

3 Data Center Beneficiaries Raising Dividends Up to 60% ↗

January 19, 2026

Via MarketBeat

5 Drone and Defense Stocks Catching Major Momentum in 2026 ↗

January 19, 2026

Insiders Are Selling These 3 High-Flying Stocks ↗

January 19, 2026

Via MarketBeat

High Risk, High Reward: 3 Healthcare Stocks to Watch in 2026 ↗

January 19, 2026

Via MarketBeat

Recent Quotes

View More

Stock Quote API & Stock News API supplied by www.cloudquote.io

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.

© 2025 FinancialContent. All rights reserved.

>