TANAKA PRECIOUS METAL TECHNOLOGIES Succeeds in Developing High-Performance Palladium Alloy Hydrogen Permeable Membrane Operable in the Low-Temperature Range of 300 degrees C

TOKYO, Sept 12, 2025 - (JCN Newswire) - TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd. (Head Office: Chuo-ku, Tokyo; Representative Director & CEO: Koichiro Tanaka), a company engaged in the industrial precious metals business of TANAKA, announces the successful development of a palladium (Pd) alloy hydrogen permeable membrane operable in the low temperature range around 300°C. Compared to conventional products, this product features high hydrogen permeation performance while operating at lower temperatures. Provision of this product’s samples is scheduled to start on or after September 15, 2025.

An academic presentation regarding this product will be made at The Japan Institute of Metals and Materials’ “2025 Fall Meeting,” which will be held at Hokkaido University from September 17 to 19, 2025.

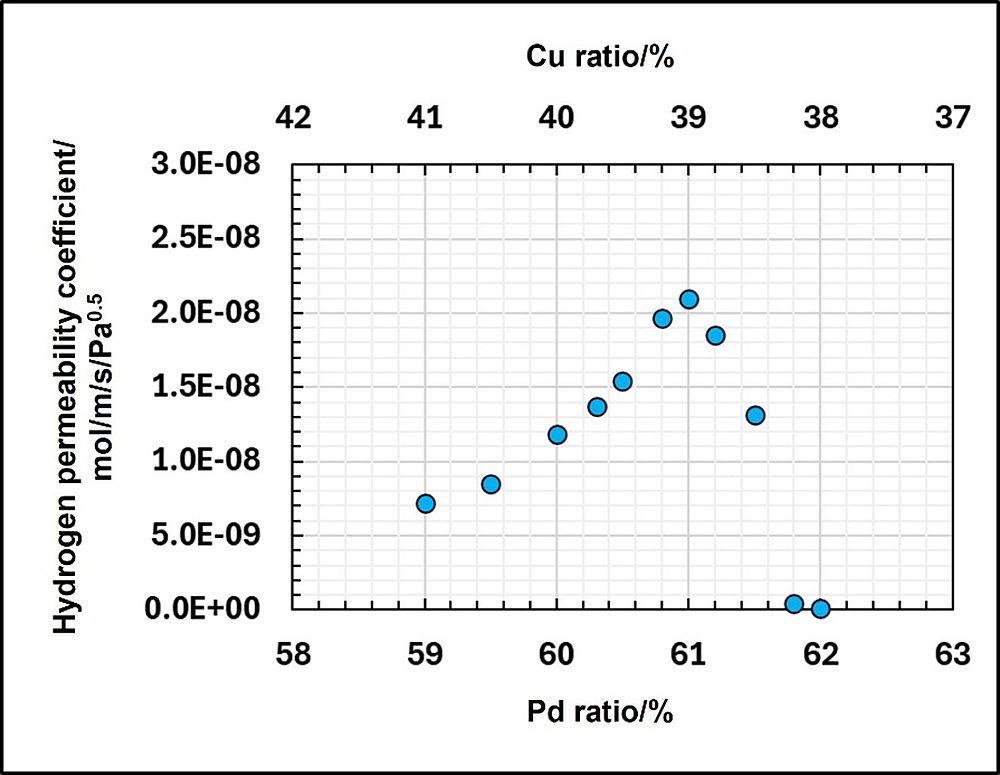

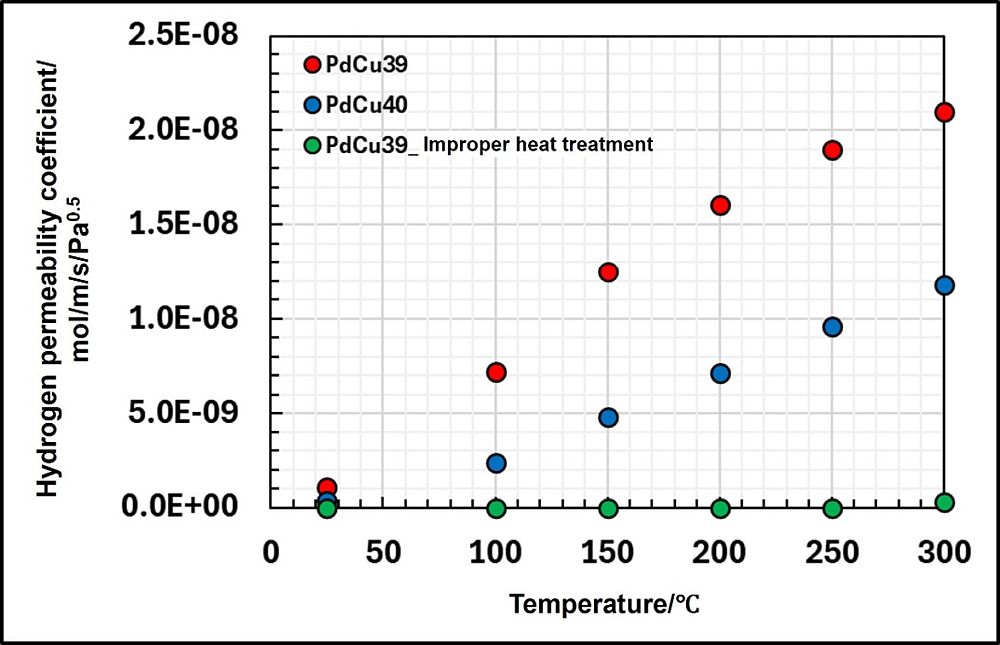

Among PdCu alloy membranes, PdCu40 (an alloy with 60% palladium content and 40% copper content) is known to exhibit the highest hydrogen permeation performance. However, hydrogen purification using PdCu40 required operation at high temperatures of around 400°C. TANAKA focused on the palladium content ratio in PdCu-based hydrogen permeable membranes and successfully maximized the performance of PdCu-based hydrogen permeable membranes with PdCu39 (an alloy with 61% palladium content and 39% copper content).

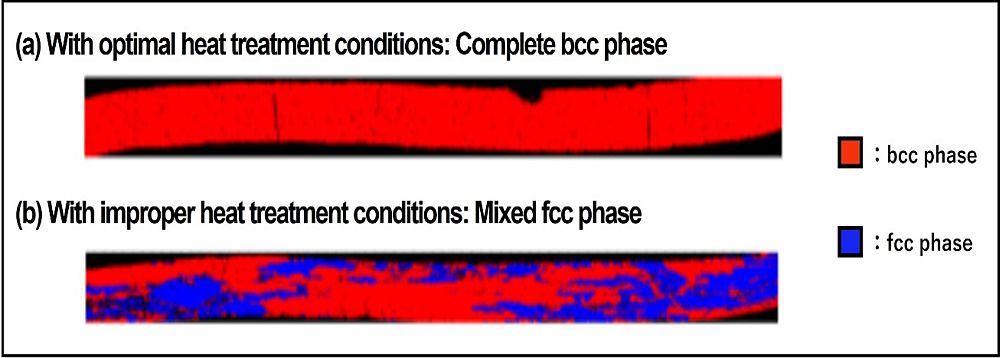

Previously, the high hydrogen permeation capability of PdCu39 was not recognized. This was because even a slight fcc phase (*1) presence would significantly reduce hydrogen permeation performance, and achieving a complete bcc phase (*2) was considered difficult. However, by applying proprietary heat treatment methods developed through decades of expertise in precious metal materials research, it became possible to obtain a complete bcc phase, leading to the commercialization of this product.

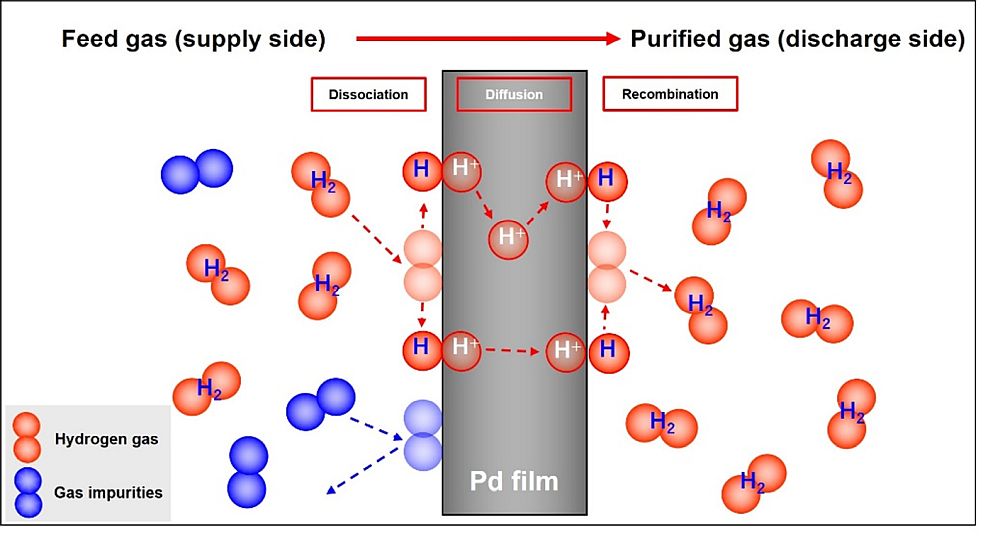

With recent advances in hydrogen purification technologies, there is increasing demand for hydrogen permeable metal membranes capable of operating at lower temperatures than previously possible. To purify high-purity hydrogen, the most common method involves purifying hydrogen gas generated from methanol-water through modules incorporating hydrogen permeable membranes. However, while hydrogen is generated from methanol-water at temperatures of around 300°C, hydrogen permeable membranes typically exhibit their performance at 400°C or higher, necessitating additional heating equipment and contributing to increased costs. Moreover, the generation of gas impurities due to heating has also posed a challenge.

This product can purify hydrogen at a low temperature of approximately 300°C, eliminating the need for additional heating equipment and reducing equipment oxidation more effectively than conventional products. Additionally, it is expected to help reduce energy costs, including electricity and CO₂ emissions.

Product Features

- Effective at low temperatures around 300°C

- High hydrogen permeation performance through achievement of complete bcc phase

- Pinhole-free membrane

- No additional heating equipment required, reducing equipment oxidation during the heating process

- Enables downsizing of hydrogen purification equipment compared to other technologies

Dimensions and Shapes Available (Prototype Samples for Evaluation)

|

Thickness |

Width |

Shape |

|

Minimum 10 µmT |

Maximum 120 mm |

Sheets (square, circular, etc.) |

*1 fcc phase: Refers to the metallic phase with a face-centered cubic crystal structure.

*2 bcc phase: Refers to the metallic phase with a body-centered cubic crystal structure.

About TANAKA

Since its foundation in 1885, TANAKA has built a portfolio of products to support a diversified range of business uses focused on precious metals. TANAKA is a leader in Japan regarding the volume of precious metals it handles. Over many years, TANAKA has manufactured and sold precious metal products for industry and provided precious metals in such forms as jewelry and assets. As precious metals specialists, all Group companies in Japan and worldwide collaborate on manufacturing, sales, and technology development to offer a full range of products and services. With 5,591 employees, the group’s consolidated net sales for the fiscal year ended December 2024 were 846.9 billion yen.

TANAKA Industrial Precious Metal Materials Portal

https://tanaka-preciousmetals.com

Product inquiries

TANAKA PRECIOUS METAL TECHNOLOGIES Co., Ltd.

https://tanaka-preciousmetals.com/en/inquiries-on-industrial-products/

Press inquiries

TANAKA PRECIOUS METAL GROUP Co., Ltd.

https://tanaka-preciousmetals.com/en/inquiries-for-media/

Press release: https://www.acnnewswire.com/docs/files/2025912_EN.pdf

]]>Source: TANAKA PRECIOUS METAL GROUP Co., Ltd.

Copyright 2025 JCN Newswire . All rights reserved.

More News

View More

Recent Quotes

View MoreQuotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.