Focus Graphite Pilot Run Demonstrates Significant Increase in Large and Jumbo Flake Recovery at Lac Knife

Lac Knife Graphite meets and exceeds U.S. DoD standards while delivering ~47wt.% large flake recovery for advanced material markets in recent pilot run conducted by AETC

Ottawa, Ontario--(Newsfile Corp. - September 2, 2025) - Focus Graphite Inc. (TSXV: FMS) (OTCQB: FCSMF) (FSE: FKC0) ("Focus" or the "Company") a Canadian developer of high-grade flake graphite deposits in Quebec, is pleased to announce results from a continuous pilot beneficiation program performed by American Energy Technologies Company ("AETC") on its 100%-owned Lac Knife project. The adjustment from 97.8% total graphite content ("TGC") to 95% TGC resulted in a substantial increase in coarse flake recovery. Large and jumbo flakes increased from approximately 33% to 47%, materially improving economics and diversifying market opportunities in a product portfolio approach planned by Focus.

To achieve these results, Focus commissioned AETC to run an upstream beneficiation circuit consisting of 18 processing units connected in series in a continuous locked-cycle campaign. Over 800 kilograms of Lac Knife graphite-bearing rock was processed, producing a concentrate that not only met market specifications but also preserved natural flake size. By producing concentrate in line with real-world demand specifications, Focus maximizes downstream value while enhancing exposure to premium, non-battery markets.

In Focus's original pilot plant testing program conducted at SGS Minerals ("SGS") in Lakefield (2013-2014), the objective of achieving a graphite concentrate grade of 97.8% TGC at 90.7% total recovery was successfully met. These results formed the technical foundation of the Lac Knife Feasibility Study (updated 2023), which outlined a process plant designed to produce 50,000 tonnes per year of graphite concentrate, including 47,781 tonnes of high-grade 97.8% TGC salable concentrate from a feed grade of 14.8% TGC. The process flow sheet developed through this work includes crushing, grinding, polishing, flotation, concentrate dewatering and drying, concentrate screening and bagging, and tailings filtration and loadout. While the Feasibility Study demonstrated Lac Knife's ability to deliver ultra-high-purity graphite, subsequent market feedback confirmed that such high purities are not required - and do not command a price premium - in most anode or industrial applications.

As a benchmark, the U.S. Defense Logistics Agency ("DLA") Strategic Materials program has defined procurement specifications for natural graphite as -100 mesh concentrate. Lac Knife material comfortably exceeds U.S. defense-grade requirements, while simultaneously aligning with anode makers' specifications for EVs and stationary energy storage.

| Specification | DLA Requirement | Focus Graphite - AETC Pilot |

| Fixed Carbon (TGC) | ≥ 94% | 95.5% |

| Ash | ≤ 5% | 4.5% |

| Volatile Matter | ≤ 1.2% | 0.63 wt.% (600 °C) |

| Moisture | ≤ 0.5% | <0.5% |

| Size Distribution | <20% retained above 100 mesh; ≤20% passing below 325 mesh | D10 = 33 µm; D50 = 120 µm; D90 = 272 µm; mean 153 µm |

Table 1: DLA Strategic Materials Program Benchmark vs. Focus Graphite Lac Knife AETC Pilot Results

Note: As of August 2025, The DLA has indicated its intent to source 49,433 tonnes of natural flake graphite over the next five years (CIP-Hammond, Indiana)

Coarse graphite flakes are rare and command premium pricing in markets where physical size is the key differentiator. On October 20, 2023, China announced its restrictions on certain graphite exports to the United States and other counties, with the new regulations taking effect on December 1, 2023. These rules, requiring export permits for high-grade natural and synthetic graphite products, were introduced under the banner of protecting China's national security. Most projects worldwide produce very little of this unique material. With its coarse flake profile, Lac Knife positions Focus to supply several high-margin speciality applications:

Jumbo flake (+30, +25, +20 mesh; ~5% of total, up to 0.84 mm in size) - High-end EMI shielding in electronics and defense equipment, corrosion resistant gaskets in marine and aerospace, crucibles for specialty alloys and rare earth processing, radar absorbing and steal composites, icephobic for aircraft and ships, precursor for graphene platelets.

+50 mesh (~15%) and +80 mesh (~24%) - Expandable and expanded graphite for fire-suppressant foams. With PFAS-based aqueous film-forming foams ("AFFF"), otherwise known as forever chemicals, being phased out amid billion-dollar lawsuits, demand for safe, graphite-based alternatives is expected to surge. Processed graphite generated from these flake sizes are also used in lead-acid and premium performance alkaline batteries.

+100 mesh - Recently proven in a hypersonic rocket nozzle launch, this fraction is valued in aerospace, defense, semiconductor and advanced materials markets.

-100 mesh - Tailored for the battery-grade anode market in both EVs and stationary battery energy storage systems ("BESS") applications, ensuring compliance with global demand.

Additionally, Lac Knife graphite demonstrates exceptionally low volatile content, a critical property for the most demanding nuclear and defense applications. While many companies can produce standard battery-grade graphite, nature rarely yields deposits with such a high proportion of coarse flakes. Lac Knife's increase in large and jumbo flake recovery from approximately 33% to 47% further strengthens Focus's strategic position. This advantage not only supports advanced processing pathways but also enables the Company to deliver environmentally friendly materials to market, creating opportunities to replace PFAS-based "forever chemicals" with safer, sustainable alternatives.

"The results from this pilot program reinforce Lac Knife's unique position as one of the few graphite projects capable of delivering both defense-grade and battery-grade material at scale," said Dean Hanisch, CEO of Focus Graphite. "By achieving market-aligned concentrate specifications, we are not only positioned to supply the EV and energy storage sectors, but also to serve premium aerospace, defense, and specialty markets. This dual-market advantage reduces risk, expands opportunity, and underscores Focus Graphite's role as a strategic supplier in North America's critical minerals supply chain."

It should be noted that this pilot program was conducted on more than 800 kilograms of Lac Knife graphite, and while the results are consistent with expectations, they may not fully represent the variability of the entire deposit. Focus intends to conduct larger scale testing in the future.

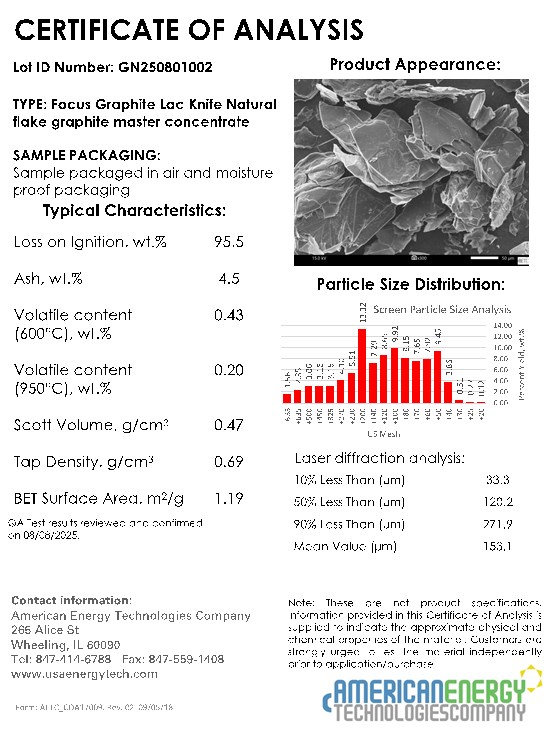

Image 1: Focus Graphite Lac Knife Natural Flake Graphite Master Concentrate, C of A

To view an enhanced version of this graphic, please visit:

https://images.newsfilecorp.com/files/1963/264723_7a22223b44e3fbc5_001full.jpg

Qualified Persons

The technical content disclosed in this news release was reviewed and approved by Réjean Girard, P.Geo. (QC), President of IOS Geosciences Inc., a consultant to the Company, and a qualified person as defined under National Instrument NI-43-101.

About American Energy Technologies Company

American Energy Technologies Co. ("AETC") is a woman-owned, privately held business which conducts operations out of the greater Chicago area. In its Wheeling, IL facility, AETC operates three business units: a manufacturing plant making battery-ready graphite and carbon materials, a pilot demonstration facility for battery materials and graphite dispersions, and a fully-functional applications laboratory supporting the above business units. Currently, AETC is one out of just three in total organizations which commercially manufacture lithium-ion battery-ready graphite in the United States. Furthermore, AETC's Wheeling, IL plant is currently the only industrial end-to-end commercial manufacturer of spherical purified surface coated natural graphite in the US. In doing so, the company develops and operates an upstream ore beneficiation, unique refining, particle spheroidization, and carbon coating technologies. AETC is both developing and produces spherical graphite (natural and synthetic), expanded graphite, partially graphitized nanostructured carbons, ultra-high purity graphite-based electrically conductive inks, paints, and coatings which find use within the industry. AETC is a proud supply chain member of electric vehicles and an approved supplier to twelve battery manufacturers and one fuel cell producer.

For more information, please visit https://www.usaenergytech.com

About Focus Graphite Advanced Materials Inc.

Focus Graphite Advanced Materials is redefining the future of critical minerals with two 100% owned world-class graphite projects and cutting-edge battery technology. Our flagship Lac Knife project stands as one of the most advanced high-purity graphite deposits in North America, with a fully completed feasibility study. Lac Knife is set to become a key supplier for the battery, defense, and advanced materials industries.

Our Lac Tetepisca project further strengthens our portfolio, with the potential to be one of the largest and highest-purity and grade graphite deposits in North America. At Focus, we go beyond mining - we are pioneering environmentally sustainable processing solutions and innovative battery technologies, including our patent-pending silicon-enhanced spheroidized graphite, designed to enhance battery performance and efficiency.

Our commitment to innovation ensures a chemical-free, eco-friendly supply chain from mine to market. Collaboration is at the core of our vision. We actively partner with industry leaders, research institutions, and government agencies to accelerate the commercialization of next-generation graphite materials. As a North American company, we are dedicated to securing a resilient, locally sourced supply of critical minerals - reducing dependence on foreign-controlled markets and driving the transition to a sustainable future.

For more information on Focus Graphite Inc. please visit http://www.focusgraphite.com

Investors Contact:

Dean Hanisch

CEO, Focus Graphite Inc.

dhanisch@focusgraphite.com

+1 (613) 612-6060

Jason Latkowcer

VP Corporate Development

jlatkowcer@focusgraphite.com

Cautionary Note Regarding Forward-Looking Statements

Certain statements contained in this press release constitute forward-looking information. These statements relate to future events or future performance. The use of any of the words "could," "intend," "expect," "believe," "will," "projected," "estimated," and similar expressions, as well as statements relating to matters that are not historical facts, are intended to identify forward-looking information and are based on the Company's current beliefs or assumptions as to the outcome and timing of such future events.

In particular, this press release contains forward-looking information regarding, among other things, the anticipated performance of graphite concentrate from the Lac Knife project; the implications of pilot plant results carried out on approximately 500 kilograms of material; the potential for recovery rates and flake size distribution to be replicated at commercial scale; the ability of the Company to meet U.S. Defense Logistics Agency, battery, and industrial specifications; the potential economics outlined in the Lac Knife Feasibility Study; and the Company's strategy to position itself as a supplier to electric vehicle, energy storage, aerospace, defense, and specialty markets.

Forward-looking statements are subject to known and unknown risks, uncertainties, and other factors that may cause actual results, performance, or achievements to differ materially from those expressed or implied by such statements. These risks and uncertainties include, but are not limited to, risks related to market conditions, regulatory approvals, changes in economic conditions, the ability to raise sufficient funds on acceptable terms or at all, operational risks associated with mineral exploration and development, and other risks detailed from time to time in the Company's public disclosure documents available under its profile on SEDAR+.

The forward-looking information contained in this release is made as of the date hereof, and the Company is not obligated to update or revise any forward-looking information, whether as a result of new information, future events, or otherwise, except as required by applicable securities laws. Because of the risks, uncertainties, and assumptions contained herein, investors should not place undue reliance on forward-looking information.

Neither TSX Venture Exchange nor its Regulation Services accepts responsibility for the adequacy or accuracy of this release.

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/264723

More News

View More

Recent Quotes

View More

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.