BWPEEK has introduced an advanced PEEK Cassette line engineered for semiconductor and electronics manufacturing, combining static-dissipative performance, chemical resistance, and RFID-enabled traceability to enhance process stability and cleanroom control.

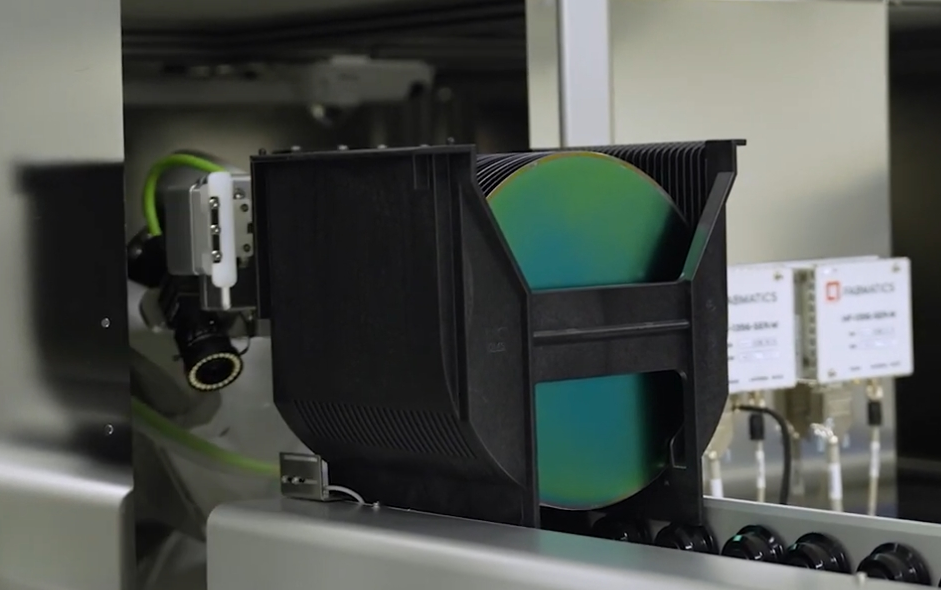

JINHUA, CHINA / ACCESS Newswire / November 10, 2025 / BWPEEK has announced the introduction of its advanced PEEK Cassette line engineered for semiconductor and electronics manufacturing environments. The development addresses the increasing need for static-dissipative carriers capable of maintaining dimensional stability, chemical resistance, and thermal reliability under demanding cleanroom conditions. Each PEEK Cassette integrates materials performance with traceable design features that align with digital manufacturing systems to enhance control and consistency in wafer handling processes.

The PEEK Cassette from BWPEEK is produced using static-dissipative grades of polyether ether ketone, designed to maintain a target surface resistance between 10⁶ and 10⁹ Ω/□. This controlled resistivity allows for the safe dissipation of electrostatic charge without full conductivity, supporting process safety and stability during wafer storage, transfer, and inspection. The polymer's inherent resistance to elevated temperatures and its chemical durability across a wide range of solvents and acids enable its use in diverse process environments including IPA, NMP, H₂SO₄, and NH₄OH. Low outgassing and particle generation characteristics further align with ISO 14644 cleanroom standards, supporting yield protection and contamination control.

BWPEEK incorporates traceability and identification features directly into each PEEK Cassette. Embedded RFID tags and laser-etched 2D matrix codes support full process visibility through MES connectivity. This approach enables digital recordkeeping for each carrier, including resin lot, mold cavity, cleaning cycle count, and exposure time. Integration with MES and SECS-GEM systems allows manufacturers to manage condition-based maintenance and lifecycle tracking, reducing variability and downtime through data-driven asset monitoring. Laser marking is selected over inks or labels to eliminate sources of particulate contamination and preserve ESD characteristics, ensuring that identification remains durable throughout extended process exposure.

Dimensional and mechanical integrity form a central part of BWPEEK's PEEK Cassette specification. Geometric tolerances such as slot pitch, parallelism, flatness, and runout are maintained to support compatibility with robotic loading and automated transfer systems. Process-critical characteristics are verified after thermal cycling and cleaning to confirm repeatable alignment and seating performance. Each cassette undergoes ESD compliance testing under controlled humidity, followed by validation of surface resistance uniformity and volume resistivity within the defined specification window.

The PEEK Cassette line supports direct application in semiconductor fabs and electronics assembly lines, including wafer storage, drying, pre-furnace conditioning, wet chemical benches, and robotic vision alignment fixtures. Qualification testing covers thermal cycling, chemical soak exposure, dimensional verification, and cleanliness assessment to confirm material stability under real operating conditions. Results from qualification studies are compiled into complete traceability documentation supplied with each batch, including resin data, inspection results, and change-control records.

Through integration of RFID-based monitoring and robust mechanical design, BWPEEK's PEEK Cassette supports consistent process control, reduced electrostatic risk, and longer operational life. These features contribute to predictable performance across high-throughput production systems. The introduction of this cassette line reflects continued alignment with industry standards and customer-defined validation protocols. All BWPEEK products are delivered with full documentation including certificates of conformity, material disclosure, and dimensional reports. Technical details and further specifications for BWPEEK's PEEK Cassette range can be accessed through the manufacturer's official information platform at peekmaterials.com.

MEDIA DETAIL

Contact Person Name: Media Relation

Company Name: BWPEEK

Email: sales@peekmaterials.com

Website: https://peekmaterials.com/

SOURCE: BWPEEK

View the original press release on ACCESS Newswire