IperionX Limited (NASDAQ: IPX, ASX: IPX), a leader in titanium metal production, is pleased to announce it has achieved the UL Environmental Claim Validation Procedure 2809 for its 100% recycled, low-carbon titanium metal powder.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230615920750/en/

(Graphic: Business Wire)

UL Solutions (UL) is a global leader in sustainability standards, and IperionX’s low carbon titanium is the first commercial titanium metal powder for additive manufacturing to achieve UL validation for 100% recycled content.

UL recycled content validation is important as titanium metal powder for additive manufacturing can only be used a limited number of times before quality is impacted by contaminants or inferior powder morphology. Out-of-specification titanium powder increases the probability of defects which jeopardize the structural integrity of additively manufactured components. Additionally, titanium metal produced by the standard “Kroll Process” is energy intensive, high cost, high carbon and is hindered by low levels of circularity. The current manufacturing process for titanium products generates large volumes of titanium waste that is downcycled to the ferro-titanium market or shipped to landfill.

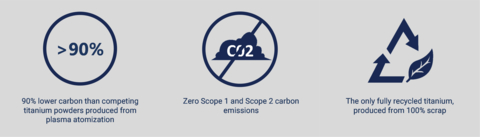

In contrast, IperionX titanium is low-carbon with zero scope 1 and 2 emissions. IperionX can uniquely use 100% scrap titanium as feedstock to produce high performance, low-carbon recycled titanium metal via a circular supply chain that doesn’t rely upon mined resources.

IperionX recently completed a life cycle assessment (“LCA”) for its 100% recycled, low-carbon titanium metal. This LCA confirmed that IperionX’s titanium has the lowest quantified life cycle carbon footprint for commercial titanium powder, with a potential life cycle carbon footprint of just 7.8 kg of carbon dioxide equivalents (“CO2e”) per kg. This forecast carbon footprint is over 90% lower than competing titanium powders produced from plasma atomization, 80% lower than from titanium ingot produced from the Kroll process, more than 50% lower than aluminium ingot, and near equal to stainless steel ingot1. Further details and a copy of IperionX’s LCA can be accessed here.

Notably, IperionX recently won the U.S. Air Force Research Laboratory Grand Challenge to produce high quality titanium metal powder from only titanium scrap feedstocks. IperionX successfully overcame a field of leading titanium companies to produce low-carbon 100% recycled titanium metal from titanium scrap or out-of-specification titanium powder feedstocks.

Major companies across the automotive, defense, bicycle, consumer electronics and green hydrogen sectors desire low carbon titanium from traceable recycled sources to meet their sustainability targets. Materials selection is an important way for manufacturers to reduce the carbon intensity of their products and yet meet demanding requirements for durability, quality and performance. IperionX offers these companies a unique and valuable solution to maximise recycled content, lower carbon footprints and still produce high performance titanium products.

Anastasios (Taso) Arima, co-founder and CEO of IperionX said:

“We are very pleased to achieve UL validation for IperionX’s 100% recycled titanium powder. This independent validation recognizes the sustainability performance of our titanium versus competing metal products. In combination with the results from our Life Cycle Assessment, UL validation indicates that IperionX has the lowest carbon, 100% recycled titanium metal on the market.”

About UL Solutions

UL Solutions delivers testing, inspection and certification services, together with software products and advisory offerings. The UL Marks serve as a recognized symbol of trust in their customers’ products and reflect an unwavering commitment to advancing UL’s safety and sustainability mission.

About IperionX

IperionX’s mission is to be the leading developer of low-carbon titanium for advanced industries including space, aerospace, electric vehicles and 3D printing. IperionX’s breakthrough titanium technologies can produce titanium products that are low carbon and fully circular. IperionX is producing titanium metal powders from titanium scrap at its operational pilot facility in Utah and intends to scale production at a Titanium Demonstration Facility in Virginia. IperionX holds a 100% interest in the Titan Project, which has the largest JORC compliant resource of titanium, rare earth and zircon rich mineral sands in the U.S.A.

Forward Looking Statements

Information included in this release constitutes forward-looking statements. Often, but not always, forward looking statements can generally be identified by the use of forward-looking words such as “may”, “will”, “expect”, “intend”, “plan”, “estimate”, “anticipate”, “continue”, and “guidance”, or other similar words and may include, without limitation, statements regarding plans, strategies and objectives of management, anticipated production or construction commencement dates and expected costs or production outputs.

Forward looking statements inherently involve known and unknown risks, uncertainties and other factors that may cause the Company’s actual results, performance, and achievements to differ materially from any future results, performance, or achievements. Relevant factors may include, but are not limited to, changes in commodity prices, foreign exchange fluctuations and general economic conditions, increased costs and demand for production inputs, the speculative nature of exploration and project development, including the risks of obtaining necessary licenses and permits and diminishing quantities or grades of reserves, the Company’s ability to comply with the relevant contractual terms to access the technologies, commercially scale its closed-loop titanium production processes, or protect its intellectual property rights, political and social risks, changes to the regulatory framework within which the Company operates or may in the future operate, environmental conditions including extreme weather conditions, recruitment and retention of personnel, industrial relations issues and litigation.

Forward looking statements are based on the Company and its management’s good faith assumptions relating to the financial, market, regulatory and other relevant environments that will exist and affect the Company’s business and operations in the future. The Company does not give any assurance that the assumptions on which forward looking statements are based will prove to be correct, or that the Company’s business or operations will not be affected in any material manner by these or other factors not foreseen or foreseeable by the Company or management or beyond the Company’s control.

Although the Company attempts and has attempted to identify factors that would cause actual actions, events or results to differ materially from those disclosed in forward looking statements, there may be other factors that could cause actual results, performance, achievements, or events not to be as anticipated, estimated or intended, and many events are beyond the reasonable control of the Company. Accordingly, readers are cautioned not to place undue reliance on forward looking statements. Forward looking statements in these materials speak only at the date of issue. Subject to any continuing obligations under applicable law or any relevant stock exchange listing rules, in providing this information the Company does not undertake any obligation to publicly update or revise any of the forward-looking statements or to advise of any change in events, conditions or circumstances on which any such statement is based.

_______________________

1 Refer to ASX announcement dated April 26, 2023 for details and sources

View source version on businesswire.com: https://www.businesswire.com/news/home/20230615920750/en/

Contacts

Anastasios (Taso) Arima, Founder and CEO

Toby Symonds, President

Dominic Allen, Chief Commercial Officer

Investors: investorrelations@iperionx.com

Media: media@iperionx.com

+1 980 237 8900

www.iperionx.com