Fujifilm's groundbreaking Aquafuze Technology has been honored with the prestigious RadTech Europe Innovation Award 2025, marking a pivotal moment for the wide-format inkjet printing industry. This recognition celebrates a decade of intensive research and development, culminating in an ink chemistry that promises to redefine efficiency, sustainability, and versatility in industrial print applications. The award underscores a significant leap forward, addressing long-standing compromises between print quality, durability, and environmental responsibility, setting a new benchmark for advanced manufacturing processes.

The immediate significance of Aquafuze lies in its ability to bridge the performance gap between traditional water-based and UV-curable inks. By combining the best attributes of both, Fujifilm (TYO: 4901) has delivered a solution that not only enhances operational workflows but also dramatically reduces environmental impact. This innovation is poised to reshape how print service providers approach production, offering a compelling blend of speed, quality, and eco-friendliness that has previously been unattainable.

The Chemistry of Innovation: Unpacking Aquafuze Technology

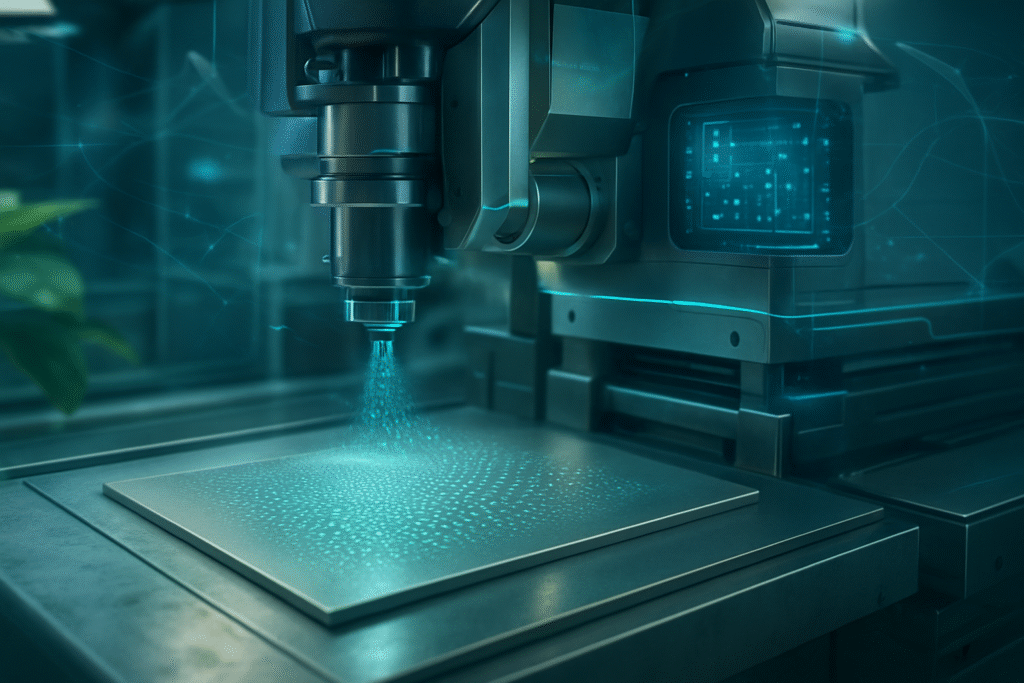

Aquafuze Technology is a proprietary water-based UV LED curing inkjet ink that stands out due to its unique chemical composition. At its core is a meticulously engineered UV-curable emulsion, stabilized within an aqueous system through a custom dispersant. This sophisticated arrangement successfully isolates UV-reactive materials from water until the precise moment of UV curing, overcoming a fundamental incompatibility that has historically plagued ink developers. This breakthrough in materials science allows for the creation of UV-curable aqueous inks that deliver superior performance across a diverse range of substrates, including various PVC types, polyester, backlit films, and materials for interior décor.

What truly differentiates Aquafuze from previous approaches is its radical hybrid performance. It delivers the instant curing, robust durability, and scratch resistance characteristic of UV inks, while simultaneously offering the flexibility, low odor, and environmental benefits of water-based inks. Unlike traditional solvent inks that demand lengthy outgassing times or latex inks requiring high curing temperatures that can distort media and inflate energy costs, Aquafuze cures instantly at a low temperature of 40-45°C using energy-efficient LED UV lamps. This eliminates bottlenecks, reduces energy consumption, and broadens the range of compatible heat-sensitive substrates. Furthermore, the ink's built-in adhesion properties and high durability negate the need for primers, optimizers, or topcoats, simplifying workflows and reducing material consumption. The print quality is also enhanced by a photopolymer dispersion that minimizes printhead nozzle clogging, ensuring stable ink ejection and consistent, repeatable results with a thin, durable, and glossy film. The technology's recognition with the RadTech Europe Innovation Award 2025, alongside an EDP Award 2025 for "Best Water-Based Inks," highlights the industry's immediate and positive reaction to this radical new approach.

Reshaping the Landscape for Tech Giants and Startups

While Aquafuze Technology isn't an AI product in itself, its implications for advanced manufacturing, automation, and smart factory integration are profound, impacting a wide array of companies. Fujifilm, as the innovator, stands to significantly benefit from this award, solidifying its position as a leader in industrial inkjet solutions. The technology's initial launch alongside the Acuity Triton, a 1.6-meter roll-fed printer developed in partnership with Mutoh (TYO: 7999), also positions Mutoh favorably, as they gain a competitive edge by offering cutting-edge, sustainable printing solutions. Print service providers globally, from large enterprises to agile startups, will find immediate advantages in adopting Aquafuze, enabling them to offer faster turnaround times, higher quality, and more environmentally friendly services.

The competitive implications for major ink and printer manufacturers are substantial. Aquafuze sets a new standard for performance and sustainability, putting pressure on competitors to innovate or risk losing market share. Companies relying on older solvent or latex ink technologies may see their products disrupted as customers increasingly demand more efficient and eco-conscious alternatives. This development could spur a wave of R&D in hybrid ink chemistry across the industry, fostering a new era of innovation. For startups in the print technology space, Aquafuze opens doors for developing new finishing solutions, automated workflows, and software integrations that can further leverage the ink's rapid curing and versatility. The market positioning for Fujifilm is strengthened not just by a superior product, but by an award that validates its long-term commitment to sustainable innovation in a demanding industrial sector.

Wider Significance: A Nod to Sustainable Manufacturing and Future AI Integration

Fujifilm's Aquafuze Technology fits squarely into the broader AI and advanced manufacturing landscape, aligning perfectly with the global push for sustainability, efficiency, and automation. The development of such a complex, high-performance material through "proprietary synthesis technology for highly functional materials and particle dispersion technology" is a hallmark of advanced materials science—a field increasingly benefiting from AI-driven research and simulation. While the ink itself isn't AI, its ability to streamline production processes, eliminate manual steps like waiting for outgassing, and operate with low energy consumption makes it an ideal component for future smart factories where AI will orchestrate entire production lines.

The impacts are multi-faceted: environmentally, the low VOC content (<15%), GHS hazard-free labeling, and Greenguard Gold certification significantly reduce the ecological footprint of industrial printing. Operationally, the immediate readiness for finishing after curing drastically cuts down production times, allowing for greater throughput and agility. Economically, reduced energy consumption and the elimination of primers translate into tangible cost savings. This milestone in sustainable industrial printing can be compared to other breakthroughs that have optimized manufacturing processes through material innovation, paving the way for more automated and intelligent production systems. The potential for AI to further optimize print settings, predict maintenance needs, and manage inventory in a facility leveraging Aquafuze inks is immense, making this a foundational technology for future AI-powered print operations.

The Horizon: From Hybrid Inks to Intelligent Print Factories

Looking ahead, the near-term developments will likely see the wider adoption of Aquafuze Technology across the industrial print sector, with Fujifilm integrating it into more of its own printer models and potentially licensing it for broader use. Print service providers will begin to showcase the tangible benefits in terms of project turnaround and sustainability credentials, driving market demand. In the long term, we can expect further advancements in hybrid ink chemistry, potentially leading to even more specialized formulations for niche applications. The efficiency gains facilitated by Aquafuze also lay the groundwork for increasingly automated and intelligent print factories.

Potential applications and use cases on the horizon include enhanced capabilities for personalized printing, on-demand manufacturing of diverse products, and the expansion into new markets requiring high durability and environmental compliance. Challenges that need to be addressed include scaling production to meet global demand, educating the market on the benefits of this new ink category, and potentially integrating Aquafuze with existing legacy systems. Experts predict that this technology will accelerate the shift towards fully automated, AI-driven print workflows where materials, machines, and software work in perfect synergy to achieve unprecedented levels of precision, efficiency, and sustainability. The focus will increasingly be on holistic solutions that integrate advanced materials like Aquafuze with intelligent process control.

A Game-Changer for Industrial Printing and Advanced Manufacturing

Fujifilm's Aquafuze Technology, recognized by the RadTech Europe Innovation Award 2025, represents a significant inflection point for industrial printing and, by extension, advanced manufacturing. The key takeaways are clear: a revolutionary ink chemistry that delivers the best of both water-based and UV-curable systems, unprecedented operational efficiency through instant, low-temperature curing, and a profound commitment to environmental sustainability. This development is not just about a new ink; it's about enabling a more agile, cost-effective, and eco-conscious future for industrial production.

While not a direct AI breakthrough, its significance in AI history lies in its enabling role for future AI-powered smart factories. By removing critical bottlenecks and streamlining processes, Aquafuze makes the entire print workflow more amenable to automation and AI orchestration. It sets a new standard for how advanced materials can drive efficiency and sustainability, which are core tenets of the ongoing fourth industrial revolution. In the coming weeks and months, the industry will be watching closely for market adoption rates, the emergence of new applications, and how competitors respond to this game-changing innovation. Fujifilm's Aquafuze Technology is poised to be a foundational element in the evolution towards more intelligent and sustainable industrial production.

This content is intended for informational purposes only and represents analysis of current AI developments.

TokenRing AI delivers enterprise-grade solutions for multi-agent AI workflow orchestration, AI-powered development tools, and seamless remote collaboration platforms.

For more information, visit https://www.tokenring.ai/.