Highlights

- Preliminary Updated Mineral Processing Flowsheet

- Following the recent leaching and impurity removal test results1, American Rare Earths is pleased to release a preliminary updated mineral processing flowsheet for the Halleck Creek Rare Earths Project (“Halleck Creek”)2. These preliminary results represent a significant milestone for the Company, which brings Halleck Creek one step closer to becoming the United States’ next producing rare earths mine.

- Preliminary Beneficiation Optimization Tests Show Promising Results

- Preliminary Reflux Classifier Concentrator (“RCC”) test results show an improvement in rare earth recoveries, with a lower mass yield when compared to spirals. In general, a lower mass yield can lead to positive operating benefits in the downstream hydrometallurgy processing and may result in lower operating and capital costs.

- There is potential for the RCC to replace the spirals as the primary beneficiation method to be used in series with the Induced Rolled Magnetic Separator (“IRMS”). The Company will seek to validate these results with planned bulk RCC testing using feed produced from the on-going comminution tests. If validated, this will likely have a positive impact to the Pre-Feasibility Study (“PFS”) economics.

- Comminution Tests Underway

- ARR expects that the on-going comminution optimization tests may yield a reduction in fines generated, which can ultimately have a positive impact to the beneficiation (i.e. ore upgrading) processing and rare earth element (“REE”) recoveries.

- ARR expects that the on-going comminution optimization tests may yield a reduction in fines generated, which can ultimately have a positive impact to the beneficiation (i.e. ore upgrading) processing and rare earth element (“REE”) recoveries.

DENVER, Nov. 10, 2025 (GLOBE NEWSWIRE) -- American Rare Earths (ASX: ARR | OTCQX: ARRNF | ADR: AMRRY) (“ARR”, “American Rare Earths” or the “Company”) is pleased to announce the release of a preliminary updated mineral processing flowsheet, in addition to progress made on the ongoing optimization work.

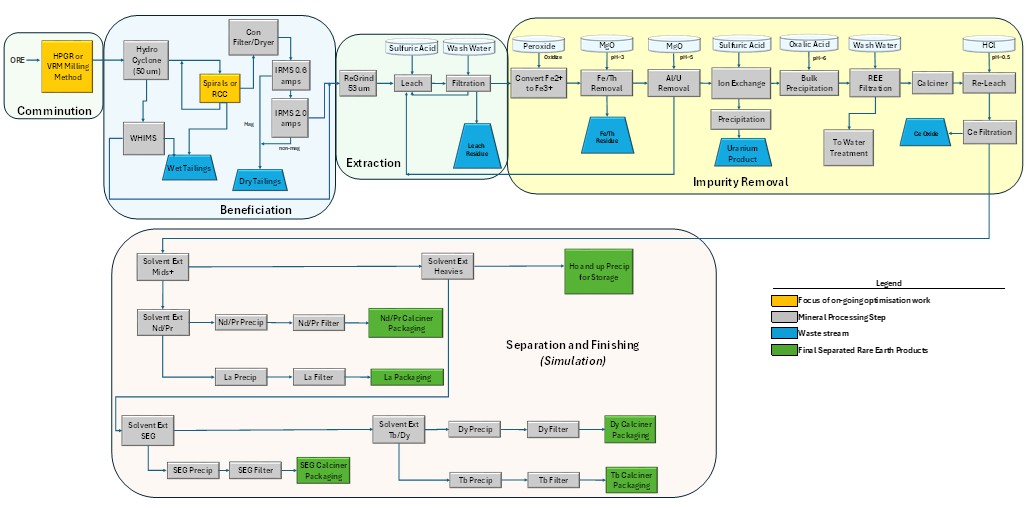

Halleck Creek is nearing the completion of a robust mineral processing flowsheet with the potential to unlock its immense rare earths resource and become the next producing REE mine in the United States. Given the positive results of recent hydrometallurgical tests3, ARR has incorporated the data received into a preliminary updated Halleck Creek mineral processing Flowsheet outlined in Figure 2.

The ongoing optimization work4 continues showing promising results. Preliminary RCC tests results using a FLS Smidth “Grade Pro RC100-40” suggest a potentially more efficient alternative to spirals as the primary beneficiation method. The RCC tests achieved lower mass yields and higher recoveries of REEs when compared to the spiral tests completed earlier in the year5. RCC units are currently deployed at scale in mining operations globally and are a proven technology. Bulk testing for the RCC, using material produced in the on-going comminution tests, will confirm whether the RCC, when used in series with the IRMS is a more effective beneficiation circuit when compared to spirals and IRMS.

As previously released6, ARR is currently testing multiple conventional comminution (i.e. milling) methods, with globally renowned experts, to optimize the front-end process and reduce the number of fines generated in the pre-processing of ore (i.e. ore milled material below a target size). If successful, the reduction of fines will have a positive impact on both the beneficiation processing and overall REE recoveries.

Remaining Steps to Finalize the Halleck Creek Mineral Processing Flowsheet:

- Create a mixed rare earths oxalate (“MREO”) from impurity removal samples by precipitating the REEs with oxalic acid. The mixed rare earth oxalate will be calcined to create a mixed rare earth oxide (i.e. the precursor to separated rare earth oxides).

- Using the MREO results, a simulation program will be undertaken to determine the optimal solvent-extraction method for the mineral processing flowsheet, this is a common and conventional practice for a PFS.

- Upon the completion of the on-going optimization tests, which will determine the most effective comminution and primary beneficiation methods, a bulk sample of Halleck Creek ore will be run through the entire preliminary updated flowsheet, except for the separation and finishing step. This will be the final gating item for the completion of the requisite datasets necessary for the forthcoming PFS report.

Importance of Optimization Work

As announced on July 18, 2025, the Company undertook a mineral processing optimization program in parallel to planned mineral processing tests. The Company has made material progress on this work through the completion of test mining7, which yielded the material needed to commence both comminution and beneficiation tests.

The objective of the ongoing comminution and beneficiation optimization testing is to find optimal and conventional processing methods to further increase the recovery of rare earth minerals from Halleck Creek’s ore. As demonstrated by the initial RCC tests, the optimization tests are already yielding positive results, which are expected to further increase confidence in both the technical and economic viability of the Halleck Creek mineral processing flowsheet.

Additional Technical Information: Reflux Classifier Concentrator Results

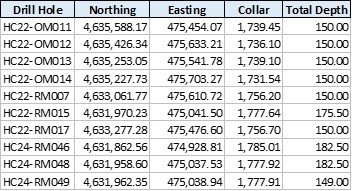

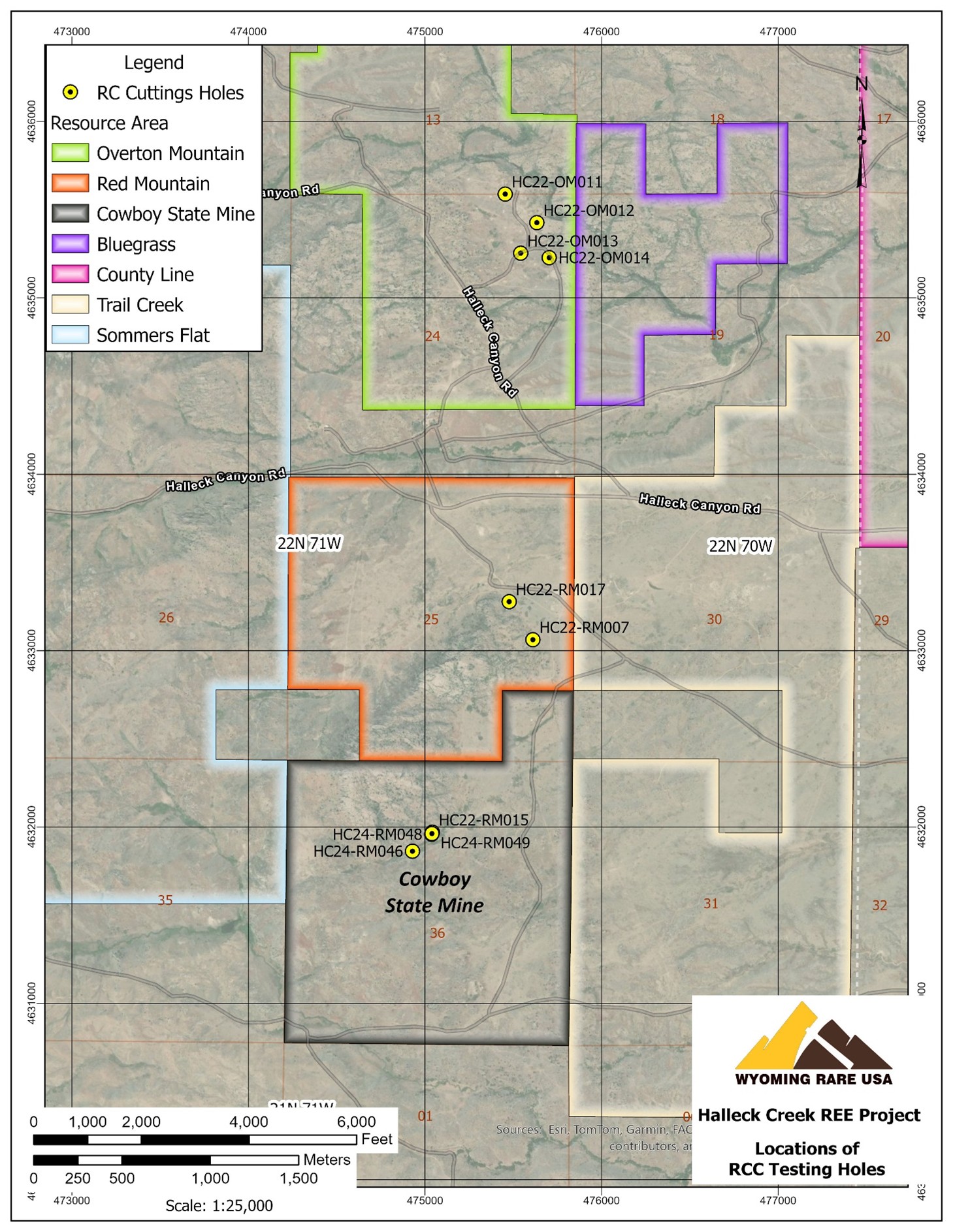

To test the effectiveness of an RCC unit at steady state ARR shipped approximately 2,255kg of Reverse Circulation (“RC”) cuttings to Nagrom based in Perth, Australia. RC cuttings from ten RC holes from Halleck Creek were shipped, see Table 1and Figure 1. Nagrom ground oversize material to 100% passing -300µm. Nagrom screened the RC cuttings into three size fractions: -300µm x +105µm (Coarse), -105µm x +45µm (Fine), and -45µm x 0µm (Ultra-fine). RCC testing was performed on the Coarse and Fine fractions. The Ultra-fine fraction is too small to effectively process using the current RCC unit at Nagrom.

Table 1 - Locations of RC Holes with cuttings shipped to Nagrom

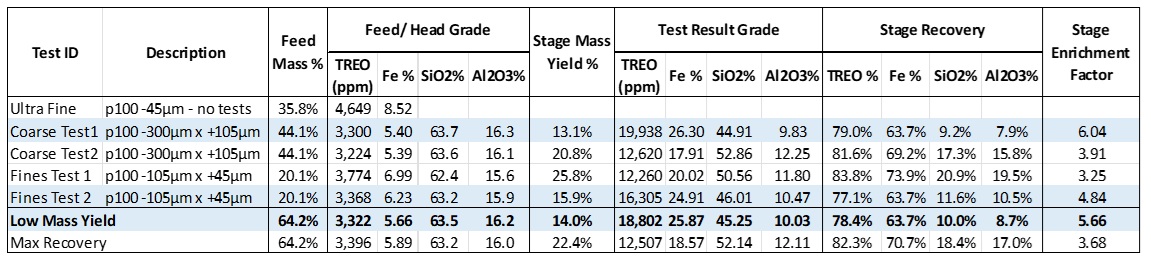

It should be noted that because RC cuttings are the feed material, there is a disproportionate amount of Ultra-fine material present. The comminution testing is expected to produce much less ultra-fine material.

Nagrom achieved excellent results from the RCC testing. The weighted average mass yield of the coarse and fine fractions is 14.0%, with a TREO recovery of 78.4% and a 5.66x enrichment faction, see Table 2. Note as RCC is a potential alternative to spirals as the primary beneficiation method, the concentrate from the primary separation is fed into the IRMS for further beneficiation. The RCC achieved excellent separation of silica and aluminum with recoveries of only 10.0% and 8.7%, respectively. In addition, significant separation of iron was achieved with only 63.7% recovery, approximately 15% less than the TREO recovery.

Table 2 - Preliminary RCC Test Results

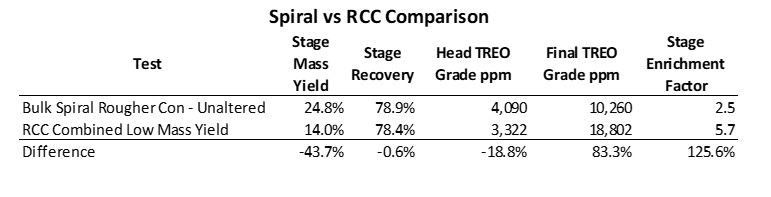

The 14.0% mass yield observed is approximately 11% points less than mass yields observed from spirals, with effectively the same TREO recovery, see Table 3. This amounts to a 44% decrease in mass yield between the two processes. Furthermore, the calculated enrichment factor is 126% greater for RCC over spirals, 5.66 and 2.5 respectively. Note both RCCs and spirals are only the primary beneficiation process to be followed by IRMS for further ore upgrading, refer to Figure 2 for additional details. In general, a lower mass yield will result in positive operating benefits, such as lower operating and capital costs, for the downstream hydrometallurgical processing.

Table 3 - Spiral vs RCC Comparison

Figure 1 - Locations of RC Cuttings Holes

Figure 2 - Updated Preliminary Halleck Creek Mineral Processing Flowsheet8

This release was authorized by the Board of American Rare Earths.

Please find the full JORC report here.

Investors can follow the Company’s progress at www.americanree.com

Competent Person(s) Statement:

Competent Persons Statement: The information in this document is based on information prepared by American Rare Earths personnel. This work was reviewed and approved for release by Mr. Dwight Kinnes (Society of Mining Engineers #4063295RM) who is employed by American Rare Earths and has sufficient experience which is relevant to the style of mineralization and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined in the 2012 JORC Code. Mr. Kinnes consents to the inclusion in the report of the matters based upon the information in the form and context in which it appears.

ARR confirms it is not aware of any new information or data that materially affects the information included in the original market announcement, and, in the case of estimates of Mineral Resources, that all material assumptions and technical parameters underpinning the estimates in the relevant market announcements continue to apply and have not materially changed. ARR confirms that the form and context in which the Competent Person’s findings presented have not been materially modified from the original market announcement.

This work was reviewed and approved for release by Mr. Kelton Smith (Society of Mining Engineers #4227309RM) who is employed by Tetra Tech and has sufficient experience which is relevant to the processing, separation, metallurgical testing and type of deposit under consideration and to the activity which he is undertaking as a Competent Person as defined in the 2012 JORC Code. Mr. Smith is an experienced technical manager with a degree in Chemical engineering, operations management and engineering management. He has held several senior engineering management roles at rare earth companies (Molycorp and NioCorp) as well as ample rare earth experience as an industry consultant. Mr. Smith consents to the inclusion in the report of the matters based upon the information in the form and context in which it appears.

About American Rare Earths Limited:

American Rare Earths (ASX: ARR | OTCQX: ARRNF | ADR: AMRRY) is a critical minerals company at the forefront of reshaping the U.S. rare earths industry. Through its wholly owned subsidiary, Wyoming Rare (USA) Inc. (“WRI”), the company is advancing the Halleck Creek Project in Wyoming—a world-class rare earth deposit with the potential to secure America’s critical mineral independence for generations. Located on Wyoming State land, the Cowboy State Mine within Halleck Creek offers cost-efficient open-pit mining methods and benefits from streamlined permitting processes in this mining-friendly state.

With plans for onsite mineral processing and separation facilities, Halleck Creek is strategically positioned to reduce U.S. reliance on imports—predominantly from China—while meeting the growing demand for rare earth elements essential to defense, advanced technologies, and economic security. As exploration progresses, the project’s untapped potential on both State and Federal lands further reinforces its significance as a cornerstone of U.S. supply chain security. In addition to its resource potential, American Rare Earths is committed to environmentally responsible mining practices and continues to collaborate with U.S. Government-supported R&D programs to develop innovative extraction and processing technologies for rare earth elements.

For further information:

| Susan Assadi Media Relations US sassadi@americanree.com 347 977 7125 | Beverly Jedynak Investor Relations US Beverly.jedynak@viriathus.com 312 943 1123 |

_______________________________________

1 See ASX release dated July 16, 2025, and October 13, 2025

2 Updated mineral processing flowsheet is not final and subject to change.

3 See ASX release dated July 16, 2025, and October 13, 2025

4 See ASX release dated July 18, 2025

5 See ASX release dated February 20, 2025

6 See ASX release dated September 23, 2025

7 See ASX release dated September 23, 2025

8 Updated mineral processing flowsheet is not final and subject to change. Note: “HPGR” = High Pressure Grinding Rolls, “VRM” = Vertical Roller Mill.

Images accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/5808d3f6-c188-4edc-9d16-9672aa94094c

https://www.globenewswire.com/NewsRoom/AttachmentNg/53b931ab-6387-4abf-a665-a76573264519

https://www.globenewswire.com/NewsRoom/AttachmentNg/06da09b3-b92b-4c4b-b3f5-dee20681dce1

https://www.globenewswire.com/NewsRoom/AttachmentNg/a9664854-39a2-4f72-bb51-e47f29d88c0c

https://www.globenewswire.com/NewsRoom/AttachmentNg/35493704-5f86-4839-ae5b-ac0f40b99ded