Hitachi: Development of an Anti-Jerk Control to Improve Ride Comfort of Electrified Vehicles and Prototype of motor torque control to improve power consumption and stability of electrified vehicles

By:

JCN Newswire

October 20, 2022 at 14:35 PM EDT

TOKYO, Oct 20, 2022 - (JCN Newswire) - Hitachi Astemo, Ltd. has developed a prototype of an anti-jerk control that improves ride comfort by reducing the back-and-forth jerk* that occurs when the vehicle stops, and a motor torque control (motor ABS (anti-lock braking system)) that improves electricity consumption, driving stability and a sense of security by maintaining appropriate wheel slippage during regenerative braking on slippery surfaces.

|

* Rate of change of acceleration. When a vehicle is brought to a stop, a vigorous acceleration with vibration and shaking tends to occur, which is called jerk

In automobile operation, during deceleration when bringing a vehicle to a stop, braking force must be controlled by loosening or strengthening the brakes appropriately according to the speed, or else jerks will occur, resulting in shaking that impairs ride comfort. To solve this issue, Hitachi Astemo developed a prototype that leverages the features of electrified vehicles.

Unlike the torque of an internal combustion engine, which is powered by fuel combustion, the torque of an electric motor is highly responsive to the driver's operation and can be increased quickly when accelerating or decelerating. Electric vehicles are also equipped with a mechanism called regenerative braking, which converts the torque into electric energy when the accelerator pedal is released. It quickly reduces the motor's rotation with torque and it generates electricity while uses torque for the braking force.

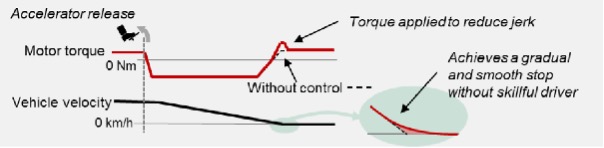

Hitachi Astemo has developed an anti-jerk control system that takes advantage of the motor's torque characteristics and the braking power of regenerative braking. The system will suppress jerks by appropriately controlling the amount of torque to optimize the motor's braking power when the accelerator pedal is released. With this control, even ordinary drivers can easily achieve smooth stops with little jolting achieving the same results as those of a skilled driver.

When driving on icy and slippery road surfaces, the regenerative braking alone could cause the tires to slip, which in turn reduces steering and driving stability. One way to avoid this issue is to stop the regenerative brake operation, which can suppress tire slippage, but this will reduce the amount of regenerated electric energy, which will worsen electricity consumption.

Hitachi Astemo has developed a motor torque control technology that does not stop the regenerative brake itself, but controls the torque of the drive motor according to the driving conditions of the vehicle. The technology enables the vehicle to continue regenerating electricity even during deceleration when the accelerator pedal is turned off, while controlling tire slip and stabilizing the driving condition. This enables both regeneration of electricity and a sense of security due to improved driving stability during deceleration.

The two newly developed technologies will contribute to OEM's electric vehicle development combining high driving performance with environmental performance, and thereby contribute to the popularization of electrified vehicles.

Hitachi Astemo is committed to strengthening its business and delivering technological innovation through a strategic business portfolio, which consists of the Powertrain & Safety Systems business, Chassis business, Motorcycle business, Software business and Aftermarket business. Aiming for a better environment globally and growth around the pillars of "green," "digital," and "innovation," we will deliver highly efficient internal combustion engine systems; electric systems that reduce emissions; autonomous driving for improved safety and comfort; advanced driver assistance systems; and advanced chassis systems. Through such advanced mobility solutions, we will contribute to realizing a sustainable society and provide enhanced corporate value for our customers.

For more information, please visit the Hitachi Astemo website: www.hitachiastemo.com/en/.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.com

More News

View More

Warner Bros. Sale Rumors Heat Up: What Investors Need to Know ↗

Today 18:23 EST

Via MarketBeat

From Science Project to Solvent: WeRide’s 761% Revenue Surge ↗

Today 17:48 EST

Via MarketBeat

Via MarketBeat

Recent Quotes

View More

Stock Quote API & Stock News API supplied by www.cloudquote.io

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.

© 2025 FinancialContent. All rights reserved.

>