MHI Delivers Testing Equipment for Safety Demonstration of Nuclear Fusion Blankets for ITER in Southern France

By:

JCN Newswire

July 06, 2022 at 02:20 AM EDT

TOKYO, Jul 6, 2022 - (JCN Newswire) - Mitsubishi Heavy Industries, Ltd. (MHI) has completed delivery of testing equipment to the Rokkasho Fusion Institute in Aomori Prefecture, part of Japan's National Institutes for Quantum Science and Technology (QST), to confirm and demonstrate the safety of the "blanket," a core component of a nuclear fusion reactor. The blanket system being developed at this research center will be used as Japan's Test Blanket Module (TBM) for the ITER-TBM project, the world's first test of blanket systems in an actual reactor environment, at ITER(1), the experimental fusion reactor currently under construction in southern France. Following the delivery of testing equipment, MHI has strong intention to contribute to the development of a blanket system for the ITER-TBM project through providing other systems/components such as TBMs.

|

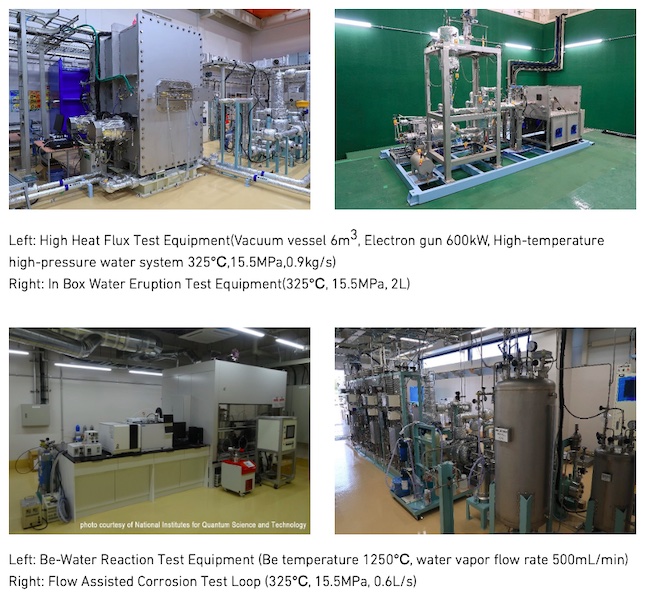

The testing equipment supplied by MHI comprises four systems, the High Heat Flux Test Equipment, In Box Water Eruption Test Equipment, Be-Water Reaction Test Equipment, and Flow Assisted Corrosion Test Loop. These testing systems will be used for various experiments aimed at developing a blanket system for the ITER-TBM project, and to confirm its safety. The blanket is one of the components that comprises the inner wall of the fusion reactor. It is a critical component that extracts the heat generated by the reactor, as well as provides for breeding and self-sustainment(2) of tritium, which is used as fuel.

ITER is an international megaproject to demonstrate, both scientifically and technologically, the feasibility of fusion energy. ITER-TBM is a project to conduct functional demonstration testing of different TBM systems, each developed independently by four of the seven participating parties (Japan, the EU, the U.S., Russia, South Korea, China, and India). Because the results from this project will influence the relative merits of blanket systems for commercial reactors in the future, each country is actively developing TBMs with demonstrated functionality and safety. In Japan, QST, as the domestic agency for the ITER Project, is leading the development of the country's blanket system.

MHI was previously awarded contracts from QST for manufacture of core components for ITER, including five (of a total of 19) toroidal field (TF) coils(3), four of which have been shipped, and six units of the divertor outer vertical targets(4), which are currently being manufactured. MHI will continue to actively support the ITER project to develop this technology, which will be vital to the stable development of the world, and contribute to the realization of fusion energy.

(1) Fusion is the energy source that enables the sun to keep shining. The ultimate goal is achieving fusion on Earth. Fusion reactions fuse light atomic nuclei (deuterium and tritium) in a plasma environment into the heavier element of helium. Fusion reactions emit zero carbon dioxide, and their source of fuel can be extracted from seawater in virtually unlimited quantities (lithium from which tritium is derived, and deuterium). Fusion energy is expected to provide fundamental solutions to many of the world's energy and environmental problems.

(2) Fusion reactors use deuterium and tritium as fuel. Neutron irradiation of a lithium compound in the blanket is used to produce and supplement the tritium that is consumed in the reaction process (self-sustainment).

(3) For details on the TF coils for ITER that QST ordered from MHI, see the following press release. www.mhi.com/news/210524.html

4For details on the divertor outer vertical targets for ITER that QST ordered from MHI, see the following press release. www.mhi.com/news/211213.html

About MHI Group

Mitsubishi Heavy Industries (MHI) Group is one of the world's leading industrial groups, spanning energy, smart infrastructure, industrial machinery, aerospace and defense. MHI Group combines cutting-edge technology with deep experience to deliver innovative, integrated solutions that help to realize a carbon neutral world, improve the quality of life and ensure a safer world. For more information, please visit www.mhi.com or follow our insights and stories on spectra.mhi.com.

Copyright 2022 JCN Newswire. All rights reserved. www.jcnnewswire.com

More News

View More

Via MarketBeat

A New Leader at Six Flags: Is the Roller Coaster Over? ↗

Today 12:04 EST

Via MarketBeat

Tickers

FUN

Via MarketBeat

Recent Quotes

View More

Stock Quote API & Stock News API supplied by www.cloudquote.io

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.

© 2025 FinancialContent. All rights reserved.

>