What Equipment Is Needed For Customized Socks?

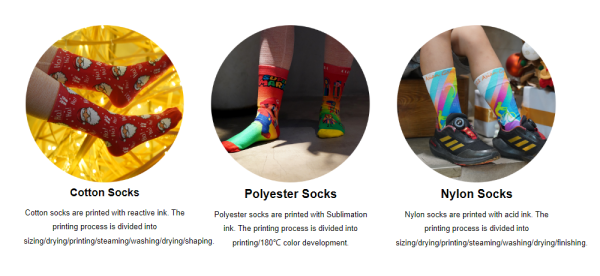

When it comes to custom socks, we refer to socks that are printed on blank socks using 360-degree seamless printing technology with uniquely rich colors and special emotions given by human beings. Socks can be broadly categorized into four groups based on their materials: cotton, polyester, wool and nylon. Different materials require different inks and print treatments.

First

let's discuss the equipment required for polyester materials. The process of polyester material is relatively simple and requires only two types of equipment, i.e., socks printer and a socks oven. With these two devices, we can complete the process of printing and color fixation.

Second

let's look at the equipment required for other materials. For cotton, nylon and wool custom socks, more equipment is needed and the process is more complex. Coating, drying, printing, steaming, washing and drying again are the processing steps required for these materials. The corresponding equipment includes printers, socks ovens, socks steamer, socks washers and socks dehydrators.

From the above, it can be seen that the procedure for print on demand socks is relatively simple, widely applicable, and has a low cost of equipment. Therefore, globally, polyester printing is more suitable for the masses.

Frequently Asked Questions

Need help? Be sure to visit our support forums for answers to your questions!

1.How do I start a digital printing business?

First of all, you need to have perseverance and determination, and leave the rest to us

2.How many machines do you have?

We have four types of sock printers and can choose the right machine according to different needs

3.What kind of nozzle does the machine use?

Our machine uses I1600 nozzle

4.How long does it take for an order to be shipped, and what is the shipping method?

We will install it, test it and ship it 7-10 days after placing the order. Shipping methods support sea, air and land transportation

5.How many colors of printing are supported?

Can support 4 colors/6 colors/8 colors selection

6.Does it support customization?

Yes. Our equipment supports customization and can be modified according to your needs

7.What is a sock printer?

Sock printer is a machine that uses inkjet technology to print patterns on socks.

Media Contact

Company Name: Ningbo Haishu Colorido Digital Technology Co., Ltd.

Email: Send Email

Phone: +86 13967852601

Country: China

Website: https://www.coloridoprinting.com/

More News

View More

Recent Quotes

View More

Quotes delayed at least 20 minutes.

By accessing this page, you agree to the Privacy Policy and Terms Of Service.