Technology Overview

In the evolving landscape of global textile manufacturing, staying ahead requires continuous innovation, cost efficiency, and sustainability. The International Textile Manufacturers Federation (ITMF) recently released its latest International Production Cost Comparison Report (IPCC), focusing on data from 2023.

This comprehensive analysis evaluates manufacturing costs across the primary segments of the textile value chain—spinning, texturizing, weaving, knitting, and finishing—while incorporating updated data from Uzbekistan and a deeper assessment of carbon footprints across all textile products.

For companies developing high-speed warp knitting machines, this report offers valuable insight into global cost drivers and environmental impact trends. By analyzing real-world production data, it helps warp knitting technology manufacturers align their innovations with industry demands for cost-effectiveness, flexibility, and reduced emissions.

Key Features and Insights1. Cost Structure Across Textile Processes

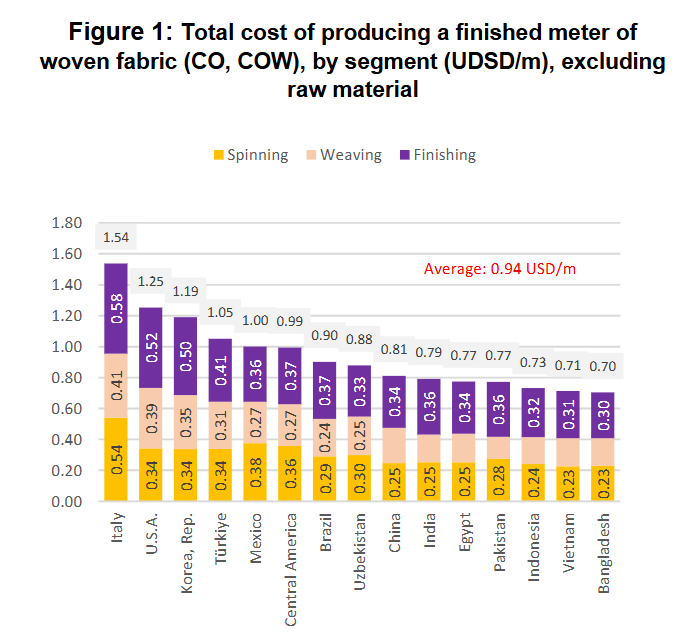

The report reveals the average global cost of producing 1 meter of cotton woven fabric using a continuous open-width (COW) finishing process was USD 0.94 in 2023 (excluding raw material costs). Among countries surveyed, Bangladesh had the lowest cost at USD 0.70, while Italy recorded the highest at USD 1.54.

- Spinning: USD 0.31/meter (Bangladesh: USD 0.23/m, Italy: USD 0.54/m)

- Weaving: USD 0.25/meter (Pakistan: USD 0.14/m, Italy: USD 0.41/m)

- Finishing: USD 0.38/meter (Bangladesh: USD 0.30/m, Italy: USD 0.58/m)

For warp knitting machine developers, this breakdown underscores the importance of optimizing production speed and minimizing secondary processing needs. Advanced electronic warp knitting systems can eliminate several steps traditionally found in woven fabric production, directly contributing to lower overall costs and higher productivity.

2. Spinning Cost Analysis: Global Benchmarks

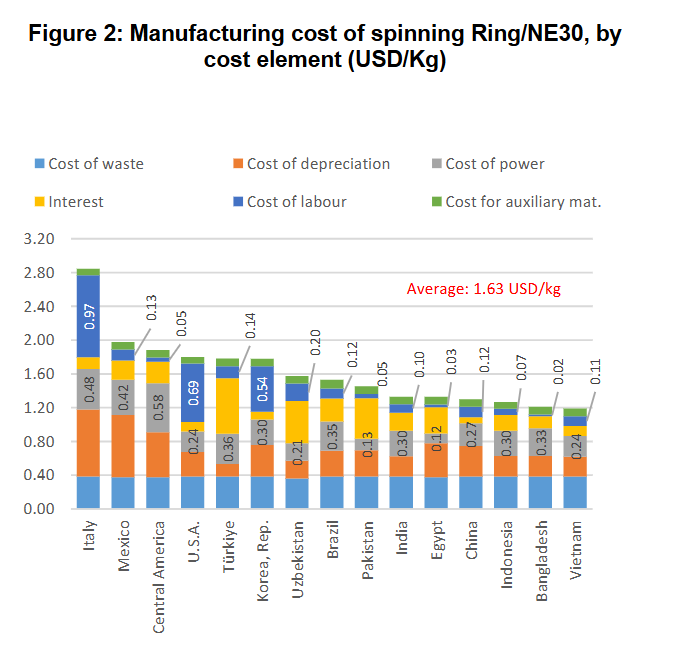

The study further analyzes the cost of spinning 1 kilogram of NE/30 ring-spun yarn, averaging USD 1.63/kg globally in 2023. Notable variations include:

- Vietnam: USD 1.19/kg

- Italy: USD 2.85/kg (highest)

Labor costs by region:

- Italy: USD 0.97/kg

- USA: USD 0.69/kg

- South Korea: USD 0.54/kg

- Bangladesh: USD 0.02/kg (lowest)

Electricity costs:

- Central America: USD 0.58/kg

- Italy: USD 0.48/kg

- Mexico: USD 0.42/kg

- Pakistan & Egypt: Below USD 0.20/kg

These insights highlight the increasing need for energy-efficient textile machinery solutions. High-speed warp knitting machines equipped with low-power servo motors, smart electronic controls, and heat-reducing mechanisms help reduce energy consumption and operational costs.

3. Environmental Impact: Carbon Footprint in Fabric Production

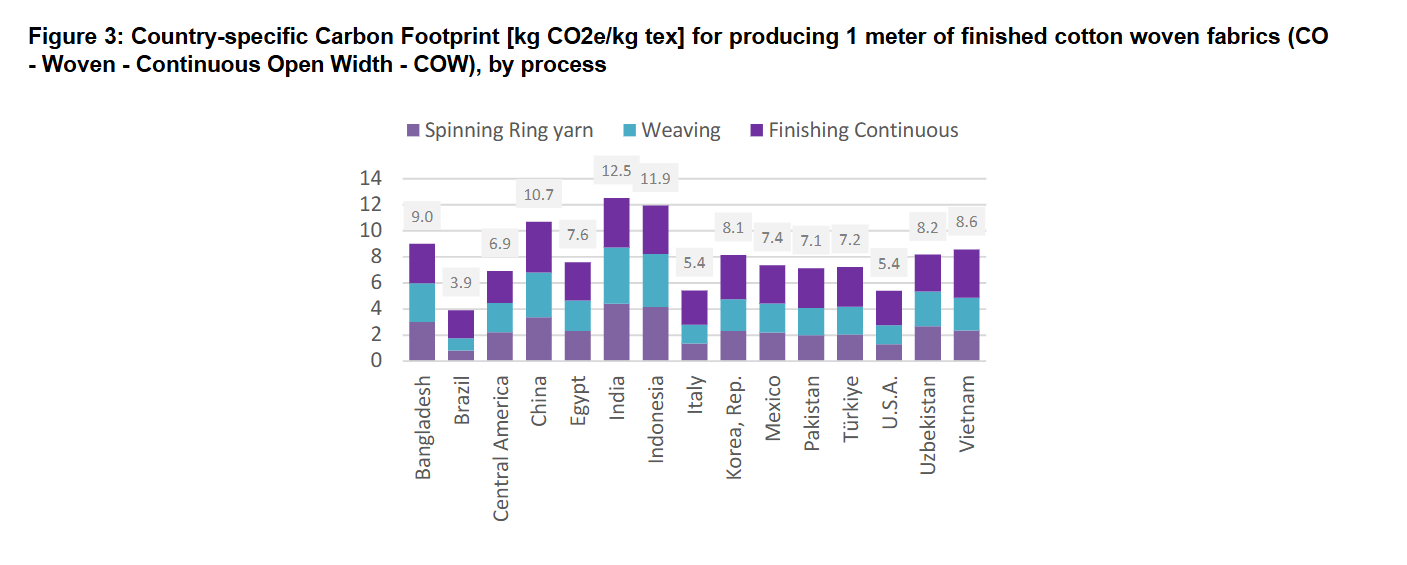

Sustainability is now a core performance metric. The IPCC report includes detailed carbon footprint analysis for 1 kilogram of cotton fabric produced via continuous open-width finishing.

Key findings:

- India: Highest emissions, >12.5 kg CO₂e/kg fabric

- China: High emissions in finishing: 3.9 kg CO₂e

- Brazil: Lowest footprint:

- USA & Italy: Efficient low-emission early stages

- Uzbekistan: Medium-level emissions across all stages

These findings reinforce the value of low-emission, high-efficiency warp knitting technology. Compared to weaving, warp knitting reduces carbon output through faster processing and minimal finishing steps, helping meet modern environmental goals.

Industry Applications

High-speed warp knitting machines are transforming textile manufacturing across a wide range of industries. Their combination of pattern versatility, cost-efficiency, and eco-friendly production offers clear advantages over traditional methods.

1. Apparel and Fashion Fabrics

- Applications: Sportswear, lingerie, outerwear, seamless garments

- Benefits: Lightweight, stretchable, breathable with high-quality finishes

- Technology Edge: Tricot and Double Raschel machines enable fast, intricate designs

2. Home Textiles

- Applications: Curtains, bed linens, upholstery

- Benefits: Dimensional stability, softness, uniform quality

- Technology Edge: Jacquard mechanisms enable rapid design transitions and multi-yarn textures

3. Automotive and Industrial Textiles

- Applications: Seat covers, airbags, sunshades, filtration materials

- Benefits: Strength, consistency, safety compliance

- Technology Edge: Controlled loop formation and technical yarn compatibility

4. Technical Textiles and Composites

- Applications: Medical fabrics, spacer fabrics, geotextiles

- Benefits: High durability, performance customization, lightweight structure

- Technology Edge: Adjustable stitch density and functional yarn integration

The GrandStar Advantage: Leading the Future of Warp Knitting

At GrandStar Warp Knitting Company, we leverage global data insights and cutting-edge engineering to build next-generation warp knitting machines. We specialize in delivering textile machinery solutions that combine speed, versatility, and efficiency, helping manufacturers stay ahead in an increasingly competitive landscape.

Whether you’re modernizing large-scale production or exploring niche technical textiles, our full portfolio—including Raschel, Tricot, Double-Raschel, and Jacquard-equipped machines—is designed to elevate your capabilities.

Call to Action

Explore how our warp knitting innovations can lower your costs, expand your design possibilities, and support your sustainability goals. Contact our expert team today to learn more about our customized solutions and discover the GrandStar advantage.

Media Contact

Company Name: Fujian Grand Star technology Co., Ltd

Email: Send Email

Country: China

Website: https://www.grandstarcn.com/